A waste sorting equipment, or a MSW, is designed to help cut down on the amount of waste that ends up in stockpiles and landfills by turning the waste into reusable products. This type of machine utilizes different types of sorting techniques in order to maximize the rate of separation for plastics, metals, organic matter and other types of substances that occurs in municipal solid waste. The end goal of waste sorting plant Indonesia is to improve the rate at which trash is recycled. There is a way to reuse biomass waste. That is the pellet mill.

Parts Of A Waste Sorting Equipment

There are several parts that make up this type of machine, and each component aids in the process of separating solid waste. One component is the programmable controller. The MSW machine is equipped with a controller that is programmed to assist in the entire sorting process.

This sorting system is able to collect signals from different sensors within the machine. As a result, the signals are conveyed to the output control contractor.

Another component of a MSW machine is the rotating screening machine. This is a patented device that combine many different sorting techniques for solid waste. It is a component that was created from many years of experience working with these types of machines. Contact manufacturers to see solid waste treatment plant design. When recycling waste, there are many paper waste. Use the egg carton machine to produce egg cartons. When you do this business, learn about egg carton machine price.

This also means that the chances of the rotating screening machine failing is very slim, and it is a machine that is very appropriate for getting rid of municipal solid waste.

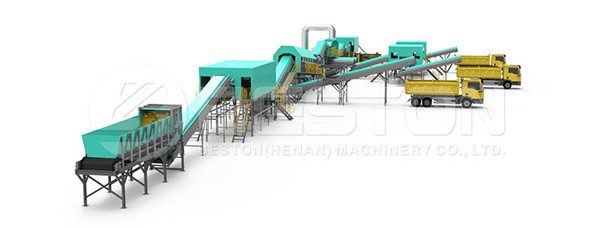

Waste Sorting Equipment for Sale with Good Quality

The bag breaker is another component and it is made from the latest technology. The bag breaker helps to integrate different types of crushing and breaking methods. Therefore, it saves energy by efficiently crushing the solid waste. Also, the broken down waste is extremely useful in the next phase of the sorting process.

The winnowing machine is a separator used in the sold waste industry and utilizes advanced separation processes. It is also able to sort solid waste into several categories.

The machine is also equipped with two different hole sizes. One hole is bigger than 50 mm and the other is smaller than 50 mm. These two holes help to classify and separate solid waste based on size. See the video about this process here.

Waste sorting machines are also equipped with a deodorizing system. It is a sealed system that emits an aromatic ester. It helps to prevent bad odors from lingering in and around the solid waste sorting equipment.

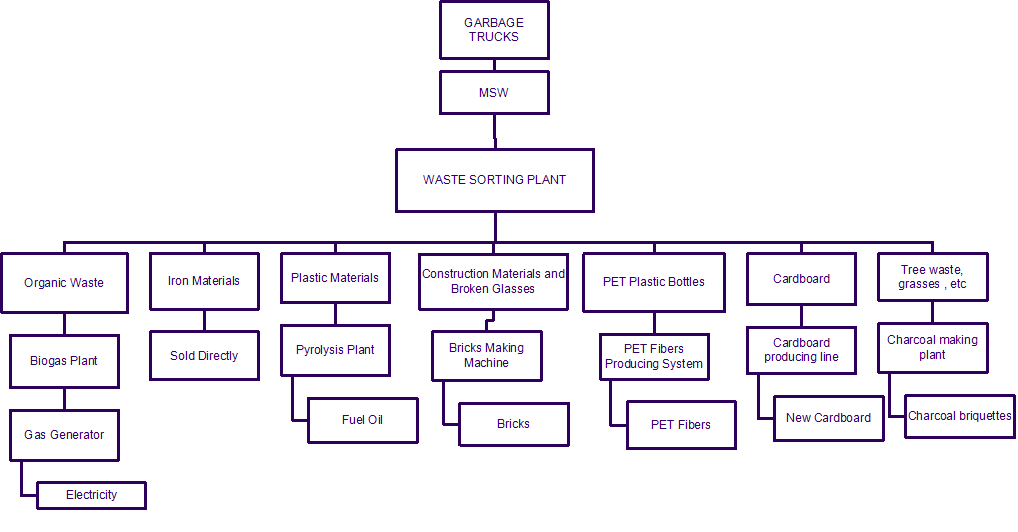

What Are Some Of The Applications For End Products?

A MSW machine offers several features that help to make it a good investment. It offers low rates of failure, great efficiency and low cost in labor. In addition, this machine can increase the time for the sorting rate by up to 90%. This is one of the reasons why these types of machines are popular in both national and international markets.

Currently, thousands of customers from multiple countries are interested in purchasing this type of equipment. So, what are some of the applications for these materials that customers can use?

Waste metal

Organic matter – fuel

Stone and sand – bricks

By implementing a municipal solid waste sorting equipment, we are able to take complete advantage of solid waste. Investors and business owners can also see increase profit in the solid waste sorting industry. Contact Beston Machinery Henan to get free quote about this project.