Charcoal production has evolved from a traditional craft into a sophisticated industrial process capable of generating significant economic returns. Deploying a charcoal making machine allows businesses to convert agricultural residues and biomass waste into high-value carbon products. This transformation not only addresses waste management concerns but also creates multiple revenue streams for local industries and entrepreneurs. Understanding the financial and operational aspects of such machinery is crucial for maximizing returns on investment.

Strategic Investment in Charcoal Making Equipment

Investing in a charcoal making machine requires careful evaluation of the machine’s capacity, operational efficiency, and durability. The charcoal making machine price varies depending on features such as automation, fuel type, and throughput. In markets like the Philippines, where agricultural by-products are abundant, selecting the appropriate model can significantly influence profit margins. High-quality machines ensure consistent output while reducing energy consumption and labor costs, providing a clear pathway to sustainable economic value creation.

Leveraging Local Biomass Resources

The economic potential of charcoal production hinges on the availability of raw materials. Techniques for how to make charcoal from coconut shell or other agricultural residues offer a dual advantage: reducing waste disposal costs and producing a premium carbon product. Coconut shells, in particular, yield high-grade charcoal with superior calorific value. By integrating these feedstocks into a production system, businesses can establish a resilient supply chain that capitalizes on locally sourced, renewable materials.

Diversification Through Complementary Products

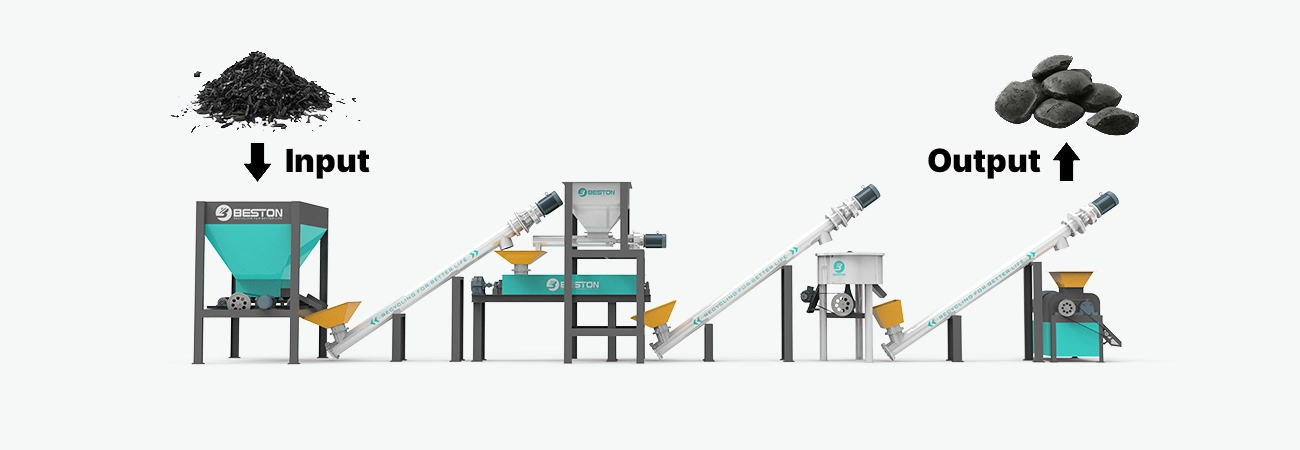

A charcoal making machine does not only produce standard charcoal. With additional equipment such as a rice husk charcoal briquettes machine, operators can expand into value-added products tailored for domestic and industrial markets. Briquettes provide a consistent burning profile and are particularly attractive for regions seeking cleaner and more efficient fuel alternatives. Diversification enhances revenue potential, mitigates market risks, and establishes a brand presence in multiple segments of the energy and cooking fuel sectors.

Economic Ripple Effects

Beyond direct production revenue, deploying charcoal making machines generates broader economic impacts. Employment opportunities arise in feedstock collection, machine operation, logistics, and product marketing. Small and medium enterprises benefit from the multiplier effect, stimulating local economies through increased trade and service demand. Furthermore, by substituting conventional fossil fuels with biomass-derived charcoal, communities can achieve cost savings and environmental benefits simultaneously, reinforcing the economic rationale for machine deployment.

Operational Efficiency and Market Competitiveness

Efficiency in charcoal production is a critical determinant of profitability. Advanced machines reduce processing time, minimize material losses, and optimize combustion parameters. In competitive markets such as the charcoal making machine Philippines sector, operational efficiency can differentiate enterprises and secure long-term contracts with industrial clients. Strategic integration of high-capacity machinery ensures consistent product quality, satisfying both commercial and consumer demand, while supporting sustainable growth.

Conclusion

Deploying a charcoal making machine transforms agricultural residues into a structured pathway for economic value creation. From strategic investment and resource optimization to product diversification and market competitiveness, the benefits extend across multiple layers of the economy. By leveraging modern equipment and innovative techniques, businesses can maximize both financial returns and environmental stewardship, cementing charcoal production as a viable and profitable industrial endeavor.