Pulp moulding technology has expanded far beyond its conventional use in protective packaging. Within the agricultural sector, it now serves as a cornerstone in the shift toward biodegradable, sustainable cultivation and post-harvest handling solutions. The integration of molded pulp equipment in farming operations is streamlining propagation systems and reducing dependence on plastic-based packaging.

Advancing Nursery Operations with Pulp Trays

Modern agriculture increasingly depends on uniformity and efficiency in seedling development. The nursery tray machine meets this demand by producing propagation trays that support consistent root formation and moisture regulation. These pulp trays offer superior porosity compared to their plastic counterparts, allowing for better aeration and root pruning—key factors in developing robust transplants.

Manufactured using recycled paper or agricultural residues, the output of the nursery tray machine is biodegradable and compostable. The trays disintegrate naturally in the soil, leaving no toxic residue. This characteristic reduces post-transplant cleanup and labor costs while supporting sustainable land management practices.

Post-Harvest Handling for Delicate Produce

The transition from field to market presents challenges for perishable goods like apples and other soft fruits. Here, the apple tray making machine plays a critical role. Designed to produce custom-formed receptacles, this machine ensures each fruit is held securely, minimizing bruising during transport and storage.

The molded pulp material used in apple trays provides a cushion that adapts to fruit contours. Unlike rigid plastic or corrugated fiberboard, these pulp trays absorb shock while facilitating moisture regulation—an essential feature for maintaining freshness over extended periods. Additionally, they are stackable, space-efficient, and cost-effective for bulk logistics.

Multifunctionality in Equipment Design

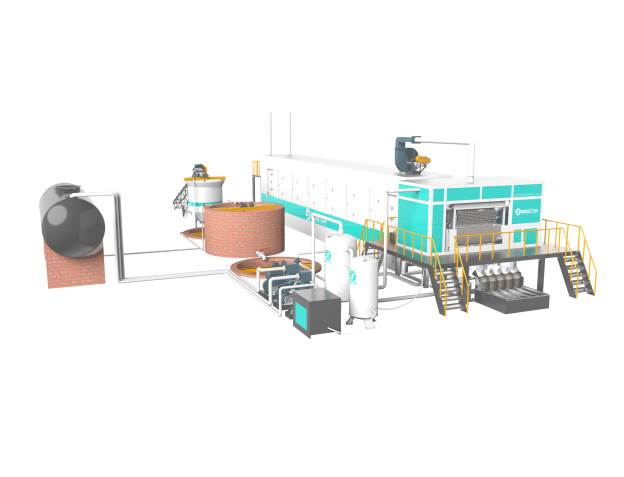

Agricultural operations benefit from integrated systems capable of producing a variety of products. A typical egg tray manufacturing plant exemplifies this flexibility. While primarily designed to manufacture egg trays, the same infrastructure can often be adapted to produce seedling trays, fruit holders, and even industrial inserts with minor tooling modifications.

This versatility stems from the modular design of modern molded pulp equipment. The forming molds, drying systems, and hot-press units can be recalibrated or replaced to accommodate changing production needs. Consequently, producers can optimize machinery usage across agricultural cycles without substantial capital reinvestment.

Sustainability Meets Precision

The environmental benefits of molded pulp extend beyond biodegradability. The production process itself requires minimal water and energy, especially when utilizing advanced drying systems such as metal drying lines or multi-layer conveyors. Wastewater can be recycled within the production loop, and raw material sourcing leverages post-consumer paper waste or agricultural fibers.

In a world where precision agriculture is converging with ecological responsibility, the role of pulp moulding machinery is becoming increasingly prominent. Whether used in a nursery for propagating seedlings or in distribution networks for fruit protection, the technology ensures a synergy between productivity and environmental stewardship.

Conclusion

The deployment of pulp moulding machines in agriculture underscores a decisive pivot toward renewable and recyclable resources. From the nursery tray machine to the apple tray making machine, each configuration within an egg tray manufacturing plant reinforces a future where performance and sustainability are not mutually exclusive but inherently aligned.