Oil sludge requires targeted thermal treatment to separate hydrocarbons from solids. Thermal desorption and pyrolysis achieve this goal through distinct mechanisms. A TDU operates on the principle of volatilizing hydrocarbons at controlled temperatures without altering their molecular structure. Short sentences emphasize clarity. Heat transfers through conduction and convection, mobilizing light and medium-range hydrocarbons for downstream condensation. The process remains strictly physical.

A pyrolysis plant, however, applies higher temperatures in an oxygen-deficient environment to induce chemical transformation. Polymer chains, heavy hydrocarbons, and complex organic residues undergo cracking reactions. This generates syngas, pyro-oil, and carbonaceous solids. The contrast lies in the fundamental distinction between volatilization and decomposition.

Temperature Profiles and Reaction Behavior

Temperature requirements diverge significantly. A thermal desorption unit typically operates between 200°C and 500°C, depending on sludge viscosity and contaminant type. These ranges are sufficient to release entrained hydrocarbons while preserving their chemical integrity. The reaction remains stable and predictable.

Pyrolysis demands more intense thermal exposure, commonly ranging from 450°C to 700°C. Such conditions trigger radical reactions, cleaving long molecular chains and producing fresh hydrocarbon species. Short statements indicate impact. The higher temperatures enable conversion of recalcitrant organic matter into recoverable resources, making pyrolysis more transformative but also more energy-intensive.

Output Characteristics and Resource Recovery

Output streams reflect the underlying chemistry. Thermal desorption generates vapor-phase hydrocarbons that condense into relatively clean recovered oil. These fractions, dominated by original hydrocarbon signatures, can be re-refined or blended into fuel streams with minimal upgrading. Solid residues retain their mineral structure with reduced organic contamination, meeting regulatory thresholds for disposal or reuse.

Oil sludge pyrolysis plant, in contrast, yields chemically modified oil with a broader distribution of light and heavy fractions. The pyro-oil may require hydrotreating or fractionation to meet commercial specifications. Syngas contributes valuable calorific energy, often recirculated to sustain reactor temperatures. Meanwhile, carbon-rich solids may serve as additives or undergo activation for specialized applications. Each product emerges from molecular restructuring rather than simple separation.

Equipment Architecture and Operational Demands

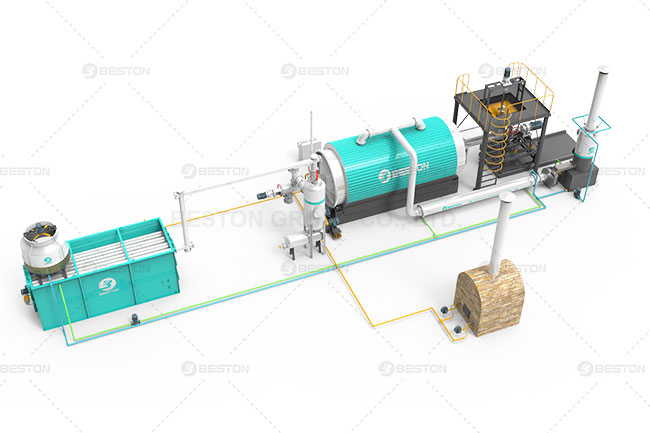

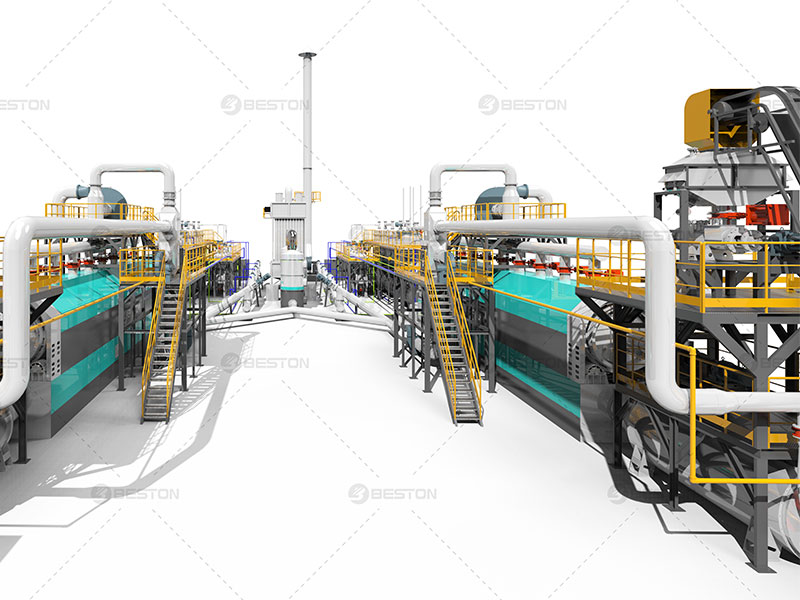

The engineering design differences between systems are substantial. A TDU relies on indirect heating through rotating drums, paddle dryers, or screw conveyors. Its modular configuration prioritizes consistent material movement, vapor extraction, and tight emissions control. Equipment tolerances remain moderate because the process avoids extreme thermal stress.

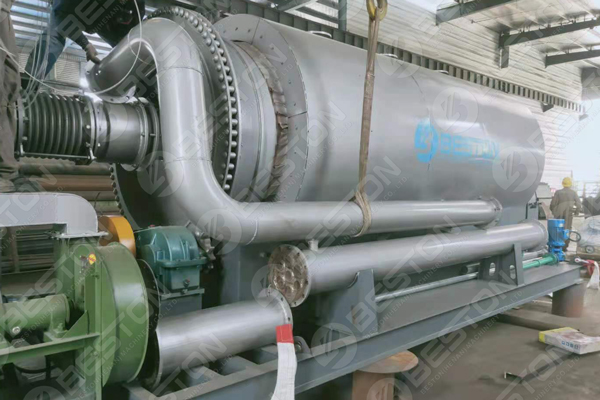

A pyrolysis plant incorporates sealed reactors, refractory linings, controlled oxygen exclusion, and sophisticated gas-handling systems. The elevated temperatures impose higher mechanical and thermal loads on the reactor shell. Elemental cracking reactions require enhanced monitoring of pressure, gas quality, and heat distribution. Short sentences emphasize complexity. System integration becomes more demanding as multiple product streams require simultaneous management.

Environmental Implications and Emission Profiles

Environmental considerations further distinguish the two processes. Thermal desorption focuses on separation without substantial chemical change, resulting in familiar emission profiles dominated by vapor-phase hydrocarbons. Exhaust gases pass through condensers, cyclones, and scrubbers to ensure compliance with local air-quality standards.To obtain cutting-edge oil sludge recovery solutions, visit: https://bestonmachinery.com/

Pyrolysis generates more complex off-gas compositions containing hydrogen, methane, light hydrocarbons, and trace organic intermediates. Effective gas cleanup is critical. Catalytic oxidizers, tar-reduction units, and particulate filters maintain regulatory compliance. Despite the complexity, the process can achieve strong environmental performance when engineered properly due to the recycling potential of syngas and reduced waste volume.

Application Suitability and Industrial Positioning

Choosing between technologies depends on the end goal. A TDU suits operators prioritizing hydrocarbon recovery without altering product chemistry. It excels in waste remediation scenarios where compliance and predictability outweigh fuel transformation. It is often preferred in upstream oilfield operations and contaminated soil treatment.

A pyrolysis plant aligns with projects seeking deeper valorization of oil sludge, converting waste into multiple revenue-generating product streams. Its transformative nature supports circular-resource strategies. Although more complex, it expands the economic potential of low-value sludge by generating fuels, syngas, and carbon-rich solids. Short summary: separation versus transformation. The distinction defines operational intent and investment direction.