A continuous pyrolysis equipment is a highly valuable investment. The equipment is well-known for its high efficiency in dealing with a large quantity of abandoned waste and turns them into useful products. What’s more, it can also avoid environmental pollution that’s brought about by practicing landfill or by incinerating these waste. See the continuous pyrolysis plant design here.

As its name suggests, a fully continuous pyrolysis equipment is primarily designed to maintain a constant pyrolysis process. With this plant, you shouldn’t expect to produce less than 45% to 52% of waste oil, 12% to 15% of steel wire, and 30% to 35% of carbon black. The working principle of this machine is similar to that of a batch waste pyrolysis plant. The entire working process of any fully continuous waste pyrolysis plant is significantly more efficient.

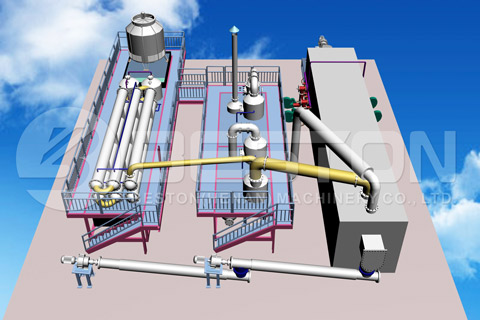

Fully Continuous Tyre Pyrolysis Plant

Working Process of a Continuous Pyrolysis Equipment

All the plastic/ waste available can be shredded using a plastic crusher. You can then feed the plastic granules directly into the machine via the feeding door. Most machines have the feeding door built with a screw insider, which can assist you in efficiently conveying the plastic granules into one of the machine’s reactor. All the plastic can then be decomposed in extremely high temperatures as it passes from the first reactor to the next. The process continues until all the waste is wholly pyrolyzed. Afterward, all the black, carbon powder will be emitted automatically to a particular tank. This web has the detailed process for you to see: www.BestonTurkey.com/.

All the available oil gas will be eventually cooled through the circulation of water, and the additional pyrolysis gas will then be recycled via pipes into the burners, where they will be heated again. A majority of these continuous pyrolysis equipment come with a water circulation system and, sometimes, an additional pyrolysis gas recycling system. These systems will assist you in saving much water and fuel. With such reliable equipment, you can reduce your cost and increase your profits.

Shipment of Besotn Continuous Pyrolysis Equipment

Benefits

Purchasing a fully continuous plastic pyrolysis plant has its share of benefits. Some of them are explained below:

– Automatic with reduced labor cost – These machines have a continuous process that involves automatic feeding and includes a discharge system. Usually, you only require one or two workers to operate the system.

– Allows large capacity – Some machines can process more than 10 tons of waste tires every day, making them efficient for large projects.

– Saves time and energy since the process is continuous

– Long service life – If you’re using a fully continuous pyrolysis equipment, the pyrolysis process will involve indirect heating of hot air. That means that the reactor won’t be much damaged; therefore, allowing a longer service life.