The egg tray manufacturing industry has seen significant advancements in recent years, particularly in the design of the paper pulp egg tray machine. These innovations aim not only to improve operational performance but also to promote sustainability, responding to growing environmental concerns and market demands for eco-friendly packaging solutions. This article explores some of the key innovations shaping the future of egg tray production, focusing on efficiency, energy consumption, and material utilization.

Advanced Technology Integration

Modern egg tray machines are increasingly incorporating advanced technologies such as automation and artificial intelligence. These enhancements streamline production processes, reduce labor costs, and increase output consistency. Automated systems ensure precise measurements of pulp and water, optimizing the molding process to produce uniform egg trays. This level of precision minimizes waste and maximizes material utilization, a crucial factor for pulp molding machine manufacturers aiming to enhance profitability while adhering to sustainable practices.

Additionally, the integration of IoT (Internet of Things) technologies facilitates real-time monitoring of the production line. This capability allows for immediate adjustments based on performance data, leading to improved efficiency. Manufacturers can track energy consumption, machine performance, and production rates, enabling proactive maintenance and minimizing downtime.

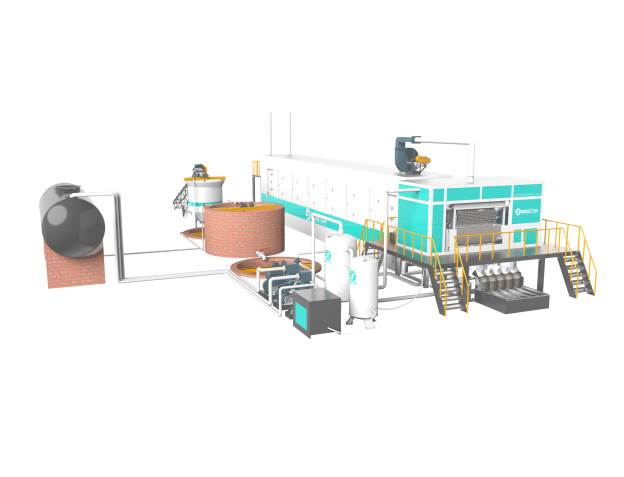

Energy-Efficient Egg Tray Drying Systems

The egg tray drying system has traditionally been one of the most energy-intensive components of the production process. Recent innovations focus on reducing energy consumption while maintaining optimal drying conditions. Modern machines now utilize advanced drying technologies, such as infrared and heat pump drying, which are significantly more efficient than conventional methods.

Infrared drying systems operate by directly heating the egg trays, thereby reducing drying time and energy usage. This method not only conserves energy but also enhances the overall quality of the trays by minimizing deformation during the drying phase. Furthermore, heat pump systems reclaim waste heat generated during production, using it to preheat incoming air, thus improving energy efficiency further.

Sustainable Material Utilization

The focus on sustainability has prompted many manufacturers to explore alternative raw materials for egg tray production. Innovations in the paper pulp egg tray machine now allow for the effective use of various recycled materials, including agricultural residues and post-consumer paper waste. This diversification of feedstock not only reduces reliance on virgin materials but also promotes a circular economy within the packaging industry.

By optimizing the pulp preparation process, manufacturers can enhance the quality of the end product while minimizing environmental impact. This shift is particularly significant as global demand for biodegradable and compostable packaging solutions continues to rise, driven by consumer preferences for eco-friendly products.

Market Availability and Accessibility

With the surge in innovations, there is an increased availability of high-performance machines in the market. The egg tray machine for sale now encompasses a variety of models, catering to different production scales and budget requirements. This accessibility empowers more businesses to invest in sustainable egg tray manufacturing solutions.

Moreover, as manufacturers increasingly prioritize sustainability and efficiency, collaboration with reputable pulp molding machine manufacturers becomes crucial. These partnerships foster innovation and ensure that companies can leverage the latest technologies and best practices in their production processes.

Compact and Modular Designs

The trend toward compact and modular designs in egg tray machines has gained traction among manufacturers. These designs not only occupy less floor space but also offer flexibility in scaling production capacity. The modular nature allows businesses to start with a smaller investment, gradually expanding their production capabilities as demand increases.

Such adaptability is particularly advantageous for small to medium enterprises looking to enter the egg tray market. Additionally, modular systems facilitate easier upgrades and maintenance, ensuring that manufacturers remain competitive in an evolving industry landscape.

Conclusion

Innovations in egg tray machine design are revolutionizing the production of eco-friendly packaging solutions. With advancements in automation, energy-efficient drying systems, and sustainable material utilization, the paper pulp egg tray machine is at the forefront of this transformation. As manufacturers continue to prioritize performance and sustainability, the egg tray industry is poised for significant growth, aligning with global trends toward more responsible consumption and production practices.