Finding a pyrolysis plant for sale is no walk in the park, especially if this is your first time. You’ve never used such machinery before, and so you don’t know how to pick the best one for your needs. You may end up choosing the wrong plant, which will cost you more money in the long run, the last thing you want, especially when running a business.

To find the pyrolysis plant, you need to do your homework and talk to the right individuals. Don’t pick the first pyrolysis plant you come across, but rather make a comparison of the various options in the market and settle for the best one. That being said, here are a few tips for finding the best pyrolysis for sale.

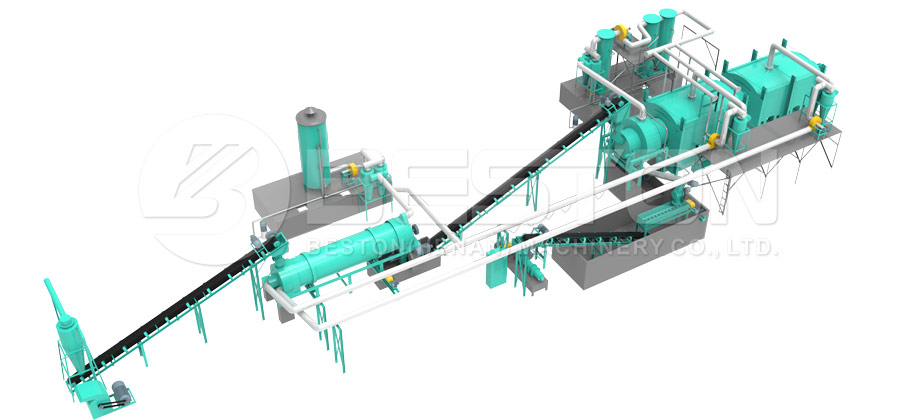

Pyrolysis Plant

Ask For Referrals

If you are a complete novice in this industry, chances are you don’t know where to begin. You may not even know the best manufacturers in the field and have a steep learning curve. To minimize the learning curve, it is best to consult those who have been in the industry for years.

These individuals know the best companies and dealers in the industry. They have used them, and so, they are more likely to recommend a company or manufacturer they know and trust. By taking this route, you will avoid picking the wrong company and machinery.

We have numerous cases of people talking to the wrong people and end up buying continuous pyrolysis plant that does not meet their needs and a company without proper customer service. So, avoid talking to individuals who aren’t in this industry.

Purchasing a pyrolysis plant straight from the parent company has an array of benefits. First and foremost, you’ll save money! Also, you get to enjoy ideal customer care. When you have an issue with your machinery, a reputable manufacturer will always have a team at hand to assist you.

Pick a small pyrolysis machine manufacturer with years of experience. If they have been in the industry for years, it means they have been doing their job right, and it will be less of a risk doing business with them. Any company that sells poor quality products or services never lasts for long.

Ensure that the company has affordable prices compared to the competition. Seek several quotes and pick one that matches your budget. However, do not fall into the trap of picking one based on the lowest price as you’re likely to get an inferior quality product.

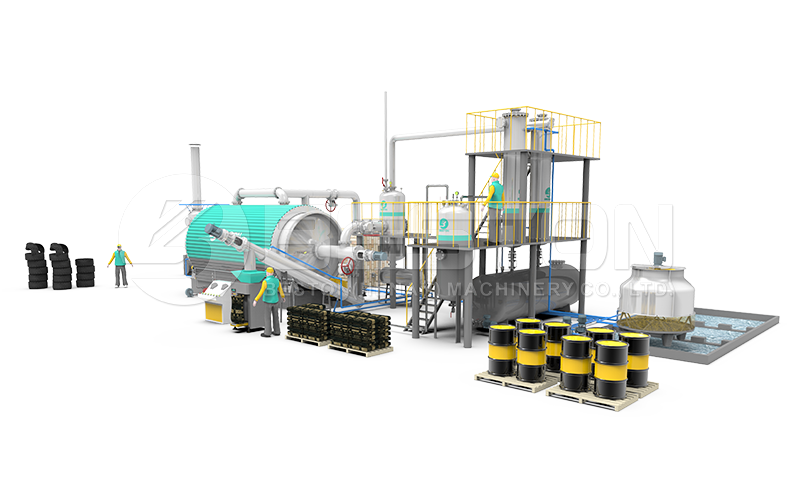

Pyrolysis Plant Installed in Korea

Online Research

Last but not least, you can find a pyrolysis plant online. Despite the assumed convenience, it’s hard to come across a reputable online dealer. So, you will need too do your homework and pick a company that checks your boxes, everything from price to quality and customer care. Find more relevant information on the reliable pyrolysis plant manufacturer.

To ensure you pick the right company, read online reviews. These reviews are from people who have used the machines before, thus giving you a genuine look at what the company offers and how they operate when it comes to issues like maintenance, spare parts etc.