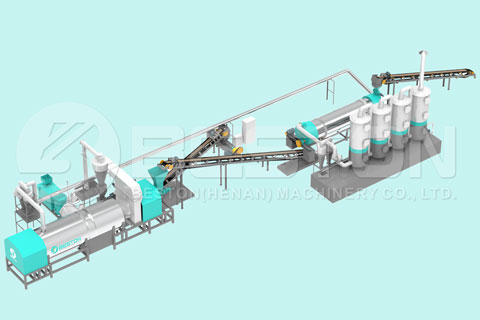

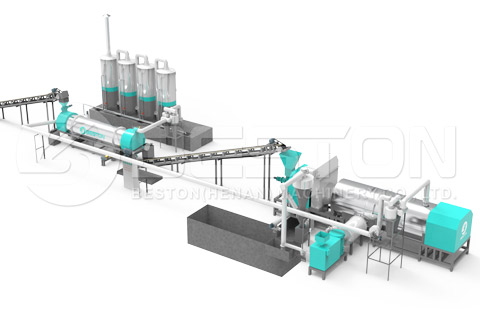

Coconut charcoal making machine for sale by the leading manufacturer has deemed this product a truly self researched plant. These machines are known for being the best on the market when it comes to processing coconut shells for the purpose of charcoal. These state-of-the-art machines ensure that the coconut shells are properly dried before processing. Read on as we dive further into the coconut shell charcoal machine.

Shipment of Beston Coconut Charcoal Making Machine

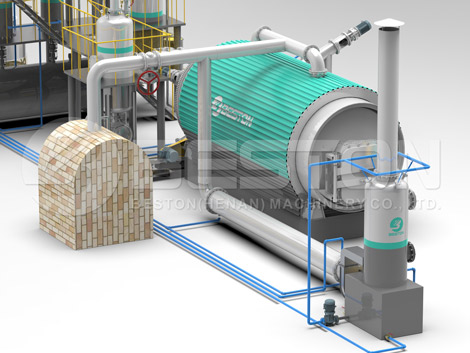

The machines also feature double cylinders and a specially designed cylinder crafted from stainless steel to ensure that it makes contact with fire directly. However, the insides are typically heated with the use of excess heat that is produced during the process. Due to the specially lowered double-layer design, the heating source makes excellent contact with the machine during operation. Hence, efficiency is pretty high from the start of the carbonization process.

Additionally, the lower layers serve to reuse eat as a means of flash steaming the raw materials. This stage is also known as the second stage of the charcoal making process. Within these machines, heat is essentially used roughly three times as a means of saving energy. Contact manufacturers to get the biomass pyrolysis plant cost.

When it comes to getting the process started, there are a couple of basic requirements that must always be met. These are as follows:

*All raw material should be properly cracked and their size should not be more than 20 millimeters.

*The moisture content should always be kept below 50% since this affects the speed of the process.

Coconut Shell Charcoal Machines for Sale

*When the end product is used, it has been known to contain a caloric value of over 5500 kcal.

*The combustible gas produced during the process is usually recycled and used as a heating source instead of the other substances such as coal.

*Any form of tail gas produced is readily passed through the dedusting system and purified.

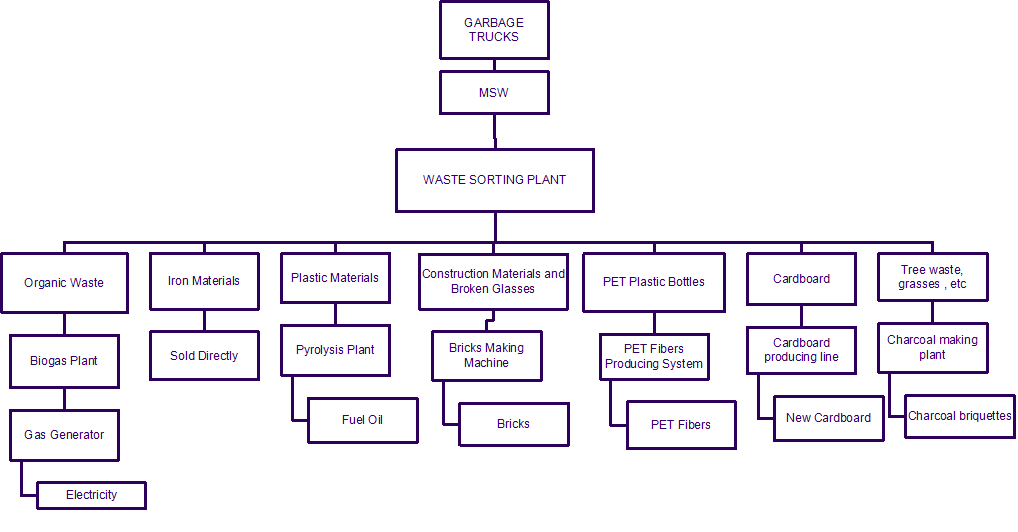

The charcoal produced from the sewage sludge pyrolysis plant are essentially useful and can be used in a series of different industries. Some of these include:

*Utilized within factories or for daily purposes such as Shisha charcoal or in BBQ.

*Charcoal can be sold to various markets as a fuel source.

*The charcoal can also be milled and exported to various international markets.

*If the charcoal undergoes further processing, it can then be converted into activated carbon for treating water during recycling processes.

*Can be used in various fields as well as for road bricks.

*Charcoal is also widely used as a means of altering the overall soil conditions.

*The heating efficiency is continuously recycled during the process.

*Raw materials are never in contact with any smoke. Hence, the wind within the machine will not contaminate it at all.

*Protects the environment from added pollution.

As we conclude, we have just looked at the carbonization furnace (https://bestonmachinery.com/biochar-production-equipment/reactor/). We have also gone into some more information on the process as well as the various advantages of it. So, if you’re looking for a profitable investment for this coconut charcoal making machine, this just might be the one for you!