Are you interested in a cost-effective biochar equipment? Do you wish to safeguard the environment from waste and make money at the same time? If so, consider installing the biochar making machine for sale. Many businesses are already earning huge profits from the innovative biochar machines, and you could be the next. At this point, you would like to assess the cost-benefit ratio and figure out a brief background of the plant in order to take your decision.

It’s a machine that’s capable of processing a range of biomass wastes, and this includes rice husk, saw dust, palm shell, bamboo, and others. The end product you get from the machine is high-quality charcoal with better caloric value. Additionally, the biochar maker from Beston Machinery lets you minimize sulfur and other harmful emissions to a great extent. That happens to be one of the important reasons for the increasing popularity of this recycling plant.

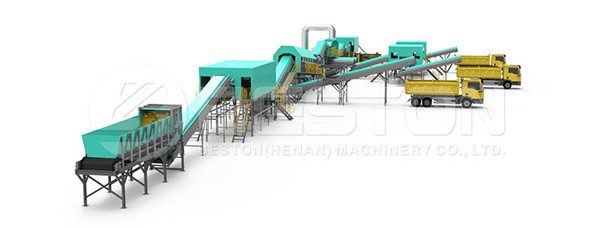

Beston Biochar Making Machine with Affordable Price

Applying, installing the biochar maker

When it boils down to buying and installing a waste recycling plant, many businesses are skeptic. This is more so with small and medium business owners. These business owners think that plenty of space may be needed to install the plant. Also, the energy cost and installation of the equipment may warrant plenty of money.

However, all such fears are just myths. The reality is the biochar plant from Beston takes up little space area and consumes less energy. You can mount the small charcoal machine in a small factory shed. Also, installing the plant requires little expenses. You could get started in the arena of biochar production within a day or two.

Advice on buying the machine

You’ll come across many suppliers of the biochar equipment. However, it’s highly advised that you order the machine from a reputed manufacturer such as the Beston Machinery. Firstly, you’ll be able to cut down your buying budget. Additionally, you’ll land a high-quality machine for making money from waste.

Beston Biochar Production Equipment for Sale

Products obtained from the biochar maker

Through this sophisticated recycling machine, you could obtain tar, charcoal, and wood vinegar. The biomass charcoal you get is more Eco-friendly and helps to conserve non-renewable energy resources on heating and cooling. Tar is a chemical element that’s used in the ship and paint industry. On the flip side, wood vinegar is used in the treatment of a number of diseases.

Features and benefits of installing the biochar machine

Now that all of your confusions and worries are resolved, you may want to figure out the perks of installing this charcoal making equipment. Although the benefits stemming from this plant are endless, some of the popular ones are detailed below.

Low investment capital

The biggest hurdle in setting up any recycling plant is the need for a big investment. Although such ventures can be highly rewarding, your initial capital is really high. However, many small business owners may not have enough capital to put on a recycling plant. However, the biochar plant from Beston Machinery comes at a modest cost. If you compare the price of this machine with other suppliers, you’ll conclude that Beston’s biochar equipment is a far better and reasonable choice.

Safety

Safety is imperative in any manufacturing unit. Although minor injuries are okay and could be treated with first-aid kits, certain injuries can be fatal and life-threatening. This is certainly true in the case of injuries occurring in heavy-duty plants such as recycling equipment. A single major accident can damage the equipment. Also, the life of the operator is in danger. The good thing is that Beston biochar machine includes some of the best safety features that are difficult to find in any other machine. In case of any problem, the equipment stops working and averts any instances of injuries.

Higher profitability

Beston’s biochar plant is heavy-duty equipment that runs continuously for 24 hours each day. Consequently, you get an uninterrupted supply of charcoal and other products in bigger quantities. Also, the machine needs less labor and works constantly without any breakages. All these things reduce the production cost and let you book big profits.

Know about more applications here: https://bestonasia.com/bamboo-charcoal-making-machine/.

Concluding words

The biochar equipment from Beston is the best carbonization machine for sale to recycle waste. By investing a low capital, you can make huge profits from waste materials. So, why not buy this plant and tap all these amazing benefits?