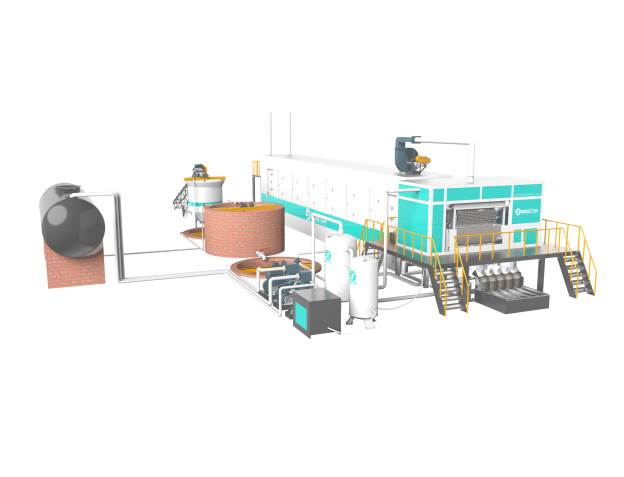

The adoption of pulp molding machines, such as the pulp egg tray making machine, plays a pivotal role in reducing waste and promoting environmental sustainability. These machines convert recycled paper and other waste materials into useful products, offering a viable solution to the growing challenge of paper waste management. The process of transforming waste paper into molded pulp products is not only energy-efficient but also contributes to a circular economy by reusing materials that would otherwise be discarded.

Waste Reduction Through Recycling

Pulp molding machines, particularly in a pulp molding plant, enable the processing of various types of paper waste, including post-consumer paper and cardboard. These materials are collected, cleaned, and then converted into pulp, which is subsequently molded into products such as egg trays, coffee cup trays, and other packaging items. By utilizing paper waste, these machines significantly reduce the need for virgin paper production, thereby conserving natural resources like trees and reducing the environmental impact associated with paper manufacturing.

In addition, the recycling process involved in the production of molded pulp products contributes to a substantial decrease in landfill waste. Without the intervention of machines like the pulp egg tray making machine, much of this paper waste would end up in landfills, where it takes years to decompose. The pulp molding process provides an efficient and eco-friendly alternative to waste disposal, promoting long-term sustainability.

Energy Efficiency and Reduced Carbon Footprint

The operation of an automatic egg tray making machine is inherently energy-efficient. Modern machines are designed to minimize energy consumption while maintaining high output efficiency. This is achieved through the integration of advanced automation technology and optimized manufacturing processes that reduce electricity usage. By reducing the amount of energy required to produce pulp-based products, these machines help lower the carbon footprint of the entire production cycle.

Furthermore, the automated nature of machines like the automatic egg tray making machine ensures consistent quality and high production speeds, which translates into less energy used per unit of output. This efficiency makes the pulp molding process an attractive alternative to conventional plastic-based packaging, which often requires higher energy input and contributes more significantly to environmental degradation.

Sustainable Packaging Solutions

Molded pulp products, produced by machines such as the coffee cup tray machine, offer a sustainable alternative to plastic and Styrofoam packaging. These materials are biodegradable, compostable, and recyclable, making them a preferred choice for environmentally conscious industries. The transition from single-use plastic products to molded pulp alternatives helps reduce plastic pollution in oceans, rivers, and other natural habitats, which is a growing concern globally.

In addition to their environmental benefits, molded pulp products are durable and capable of withstanding the rigors of transportation and storage, making them an effective choice for packaging. The ability of the pulp molding plant to produce a wide range of products from waste materials further enhances the versatility and sustainability of the production process.

Conclusion

The environmental impact of pulp molding plants in waste reduction cannot be overstated. These machines offer an effective means of recycling paper waste, reducing landfill contributions, and conserving natural resources. By providing energy-efficient, biodegradable, and sustainable packaging solutions, pulp molding technology supports a cleaner, more sustainable future. The integration of such technologies into manufacturing processes signifies a critical step forward in the global effort to reduce waste and mitigate the effects of environmental pollution.