The domain of sustainable technologies unfolds a complex tapestry, where the symphony of biochar machine takes center stage. These intricate apparatuses represent the pinnacle of engineering prowess, orchestrating the transformation of organic waste into a carbon-rich substance with profound agricultural implications.

Pyrolysis Precision

At the core of any biochar machine (also called biochar equipment) lies the elegant ballet of pyrolysis, a thermal transformation process that extracts energy from biomass. The orchestration of high temperatures, often surpassing 700 degrees Celsius, is the defining feature of this meticulous choreography. The deliberate application of heat induces the pyrolytic breakdown of organic matter, liberating volatile compounds and birthing biochar.

Temperature Calibrations

Temperature, the unsung conductor of this thermal ballet, demands precision in the design and engineering of biochar machines. The precision temperature control within these apparatuses dictates the success of pyrolysis, ensuring the optimal conditions for the creation of high-quality biochar. Advanced thermocouple technologies, akin to a maestro’s baton, guide the nuanced thermal performance.

Sensorial Harmony

In this intricate dance of pyrolysis, sensors play a pivotal role. Infrared sensors and gas analyzers, akin to vigilant sentinels, form an ensemble that monitors the volatile gases released during the pyrolytic performance. This real-time feedback loop, akin to a symphonic harmony, allows the straw/bamboo/wood/sawdust charcoal making machine to adapt its parameters dynamically, ensuring a performance of utmost precision.

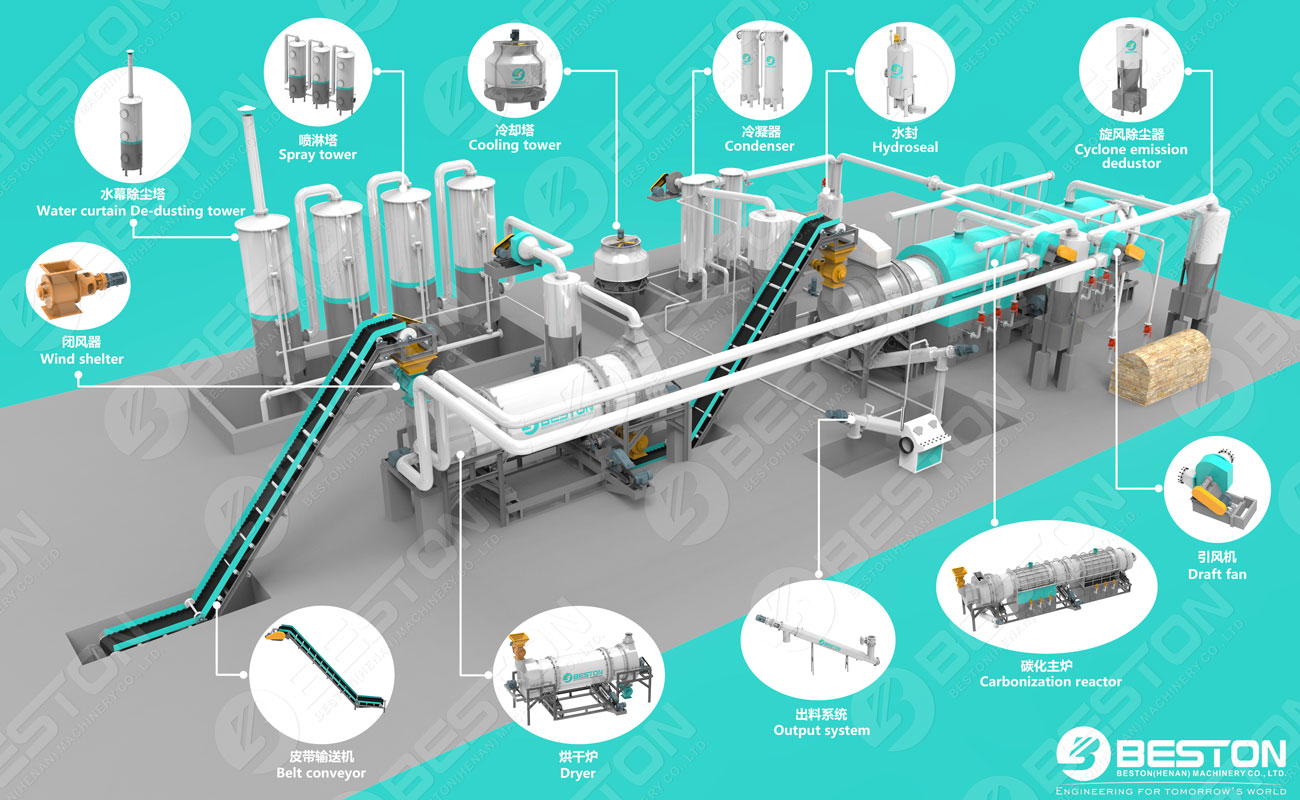

Feedstock Preparation Ballet

Before the grand overture of pyrolysis, the biochar machine dedicates attention to its prima donna – the feedstock. The optimization of feedstock preparation involves a choreography of reducing particle sizes, calibrating moisture content, and selectively choosing biomass types. This preparatory dance ensures an efficient and virtuoso pyrolytic performance.

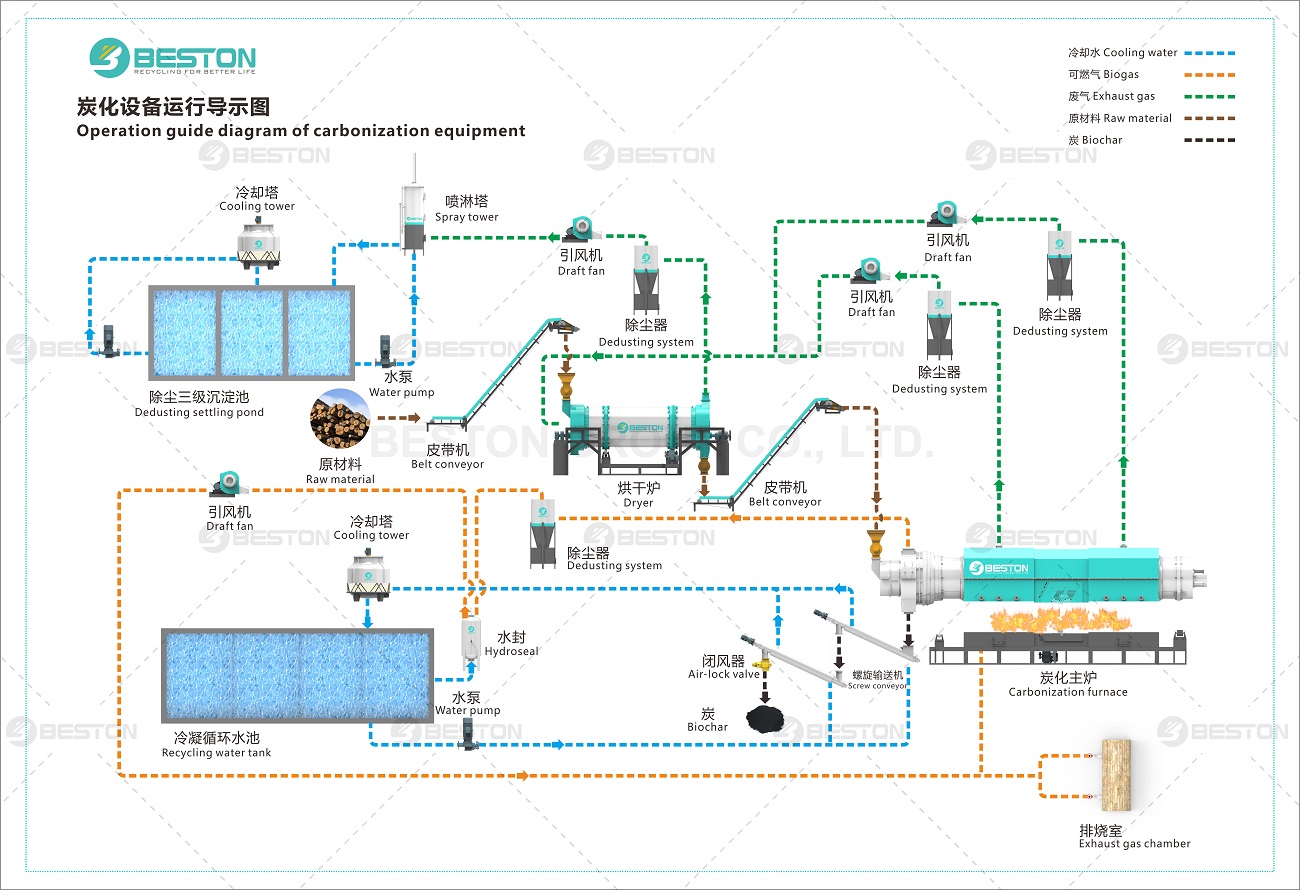

Emission Control Waltz

In the pursuit of sustainability, the biochar machine executes a meticulous dance to mitigate environmental concerns. Emission control mechanisms, including afterburners and gas scrubbers, pirouette through the pyrolytic residues. This choreographed dance ensures that emissions conform to stringent environmental standards, casting biochar production as an eco-conscious endeavor.

Structural Sonata

Beyond the ephemeral beauty of pyrolysis lies the structural sonata of the carbonizer machine. Machine design marries form with function, demanding an engineering prowess that spans material selection, structural integrity, and ergonomic considerations. Stainless steel, with its corrosion resistance, often takes center stage, embodying the resilience required for the enduring performance of the biochar machine.

Nexus of Automation and Precision

In the contemporary landscape of biochar machine design, the nexus of automation and precision engineering unfurls its transformative wings. Automated augers delicately transport feedstock into the pyrolytic crucible, guided by algorithms finely tuned to the nuances of each biomass type. The orchestration of this automated ballet enhances efficiency and reduces the reliance on manual intervention.

Scaling Up Symphony

As the demand for sustainable solutions crescendos, the biochar machine faces the challenge of scale. Scaling up production necessitates a symphony of logistics, infrastructure, and technological scalability. Industrial biochar machines, designed for voluminous biomass throughput, epitomize the integration of scale into the symphony of sustainable technology.

Quality Control Concerto

In the realm of biochar production, the quality of the final product assumes paramount importance. A meticulous biochar quality assurance concerto encompasses not only the composition of the biochar but also its physical characteristics. Sieve analyses, pH assessments, and surface area measurements contribute to the qualitative concerto that ensures each batch of biochar meets exacting standards.

Biochar Machine Economics

Beyond the technical ballet, the biochar machine faces the scrutiny of economic viability. The judicious economic analysis of biochar/charcoal machine involves a cost-benefit concerto. Initial capital investments, operational costs, and the potential revenue streams derived from biochar products intricately waltz through the financial stage. This economic ballet underpins the sustainability and widespread adoption of biochar machines.

Epilogue: A Global Opera

As biochar machines pirouette through the realms of precision engineering, automation, and sustainability, their impact resonates globally. International trends in biochar machine adoption reveal a planetary shift toward embracing these sophisticated technologies. Collaborative efforts on a global stage seek to refine the choreography of biochar production, ensuring that this elegant opera of sustainability leaves an indelible mark on the landscape of environmental stewardship.