Energy is a scarce resource, therefore we need to adopt new ways of producing energy. Biomass carbonization is one of the methods that has emerged in the past few years. Processing waste raw materials in a biomass carbonization machine to produce resources is becoming quite common. Biomass charcoal machine produce precious energy from biomass raw materials such as coconut shell, straw, wood, olive shell, sugarcane bagasse, peanut shell, bamboo, sawdust, rice husk, etc. Biomass carbonization is an effective project through which biomass raw materials are turned into artificial charcoal.

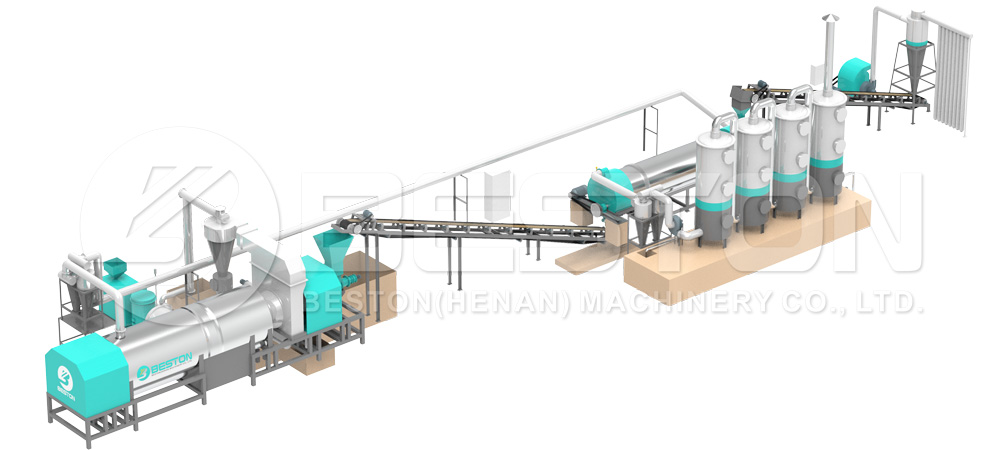

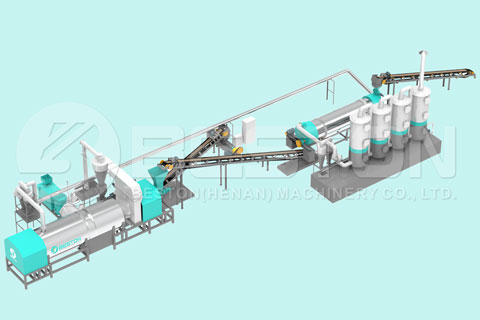

Beston Biomass Carbonization Plant for Sale

What is Carbonization?

Carbonization is a thermo-chemical procedure that facilitates the transformation of structured wood molecules, and cellulose materials into carbon and coal. It is done by the elimination of water and other volatile elements from the vegetative matter by heating.

How a Biomass Carbonization Plant Works

The process of converting biomass waste into charcoal happens in the following major stages; moisture elimination, high-temperature carbonization, purification and sulfur release, and charcoal enrichment.

1. Moisture Elimination

The level of moisture and raw material size will impact the quality of the final product. Therefore, the sawdust charcoal making machine has a dryer and shredder which reduces raw material sizes to under 50mm and the moisture level to under 20%. The shredded raw materials are placed on a conveyor belt for transfer to the next process in the carbonization chamber.

Beston Biomass Carbonization Machine for Sale

2. High-temperature carbonization

Biomass is moved to the carbonization furnace where it is subjected to high temperatures. High-temperature pyrolysis happens in this furnace which leads to the production of sulfur and other volatile gases. At the onset, traditional fuels such as wood, natural gas or coal are used to heat the furnace for at least 30 minutes. Then, after the furnace achieves the desired temperature, the biomass materials produce combustible gas which heats the furnace or dryer. The outputs of this stage are artificial coal and combustible gas. More information on carbonizer machine here.

3. Purification and releasing sulfur

The combustible gas moves to the condensation chamber. The system will discharge carbide, and the rest of the hot gas will be purified by the elimination of sulfur and smoke through smoke abatement. After desulfurization and smoke abatement, the steam is transferred to the recycle water pool.

4. Charcoal enrichment

The end product is charcoal, wood vinegar, and tar.

What are the Products of a Biomass Carbonization Machine?

After high-temperature carbonization and carbon enrichment, the main resource produced is artificial carbon that contains a rich carbon content of approximately 90%. This is a better quality product when compared to general coal that has a 55% carbon content. Also, it is an emerging kind of superior fuel with excellent flammability.

Advantages of Biomass Carbonization Machine

Improves heat utilization: A biomass carbonization facility employs unique technology that employs a ‘one fire two step’ approach. By doing this, the lower part has complete hot air engagement which increases heat utilization efficiency.

Costs savings: There is a single source of air during the entire process which leads to huge cost savings for investors.

Biomass carbonization machine have huge potential in recycling biomass waste to produce resourceful coal. This has encouraged more investors to pursue biomass projects that have a meaningful impact. Biomass carbon has a variety of uses ranging from industrial to agricultural. It can be applied in agriculture to promote soil aggregation and to improve the soil. In industrial applications, it can be used in smelting. Wood coal has been used previously as barbecue charcoal. In conclusion, it is beneficial to have a biomass carbonization machine due to the various uses of its end products. Check the small charcoal making machine here.