In many parts of the world there are huge problems with piles of agricultural waste. Sometimes it’s rice hulls, olive pits, and coconut shells, other times it’s wood sawdust, corn stalks, and wheat straw. After the big harvest there is usually an enormous pile of leftover debris that is hard to get rid of. In foreign countries it is usually burned which clogs the air and releases all of the carbon dioxide and smoke into the air. There is another solution that can be profitable and take care of gigantic piles of waste in a very short time. In fact, owners of the wood charcoal making machine can charge for dumping and then charge for the charcoal too.

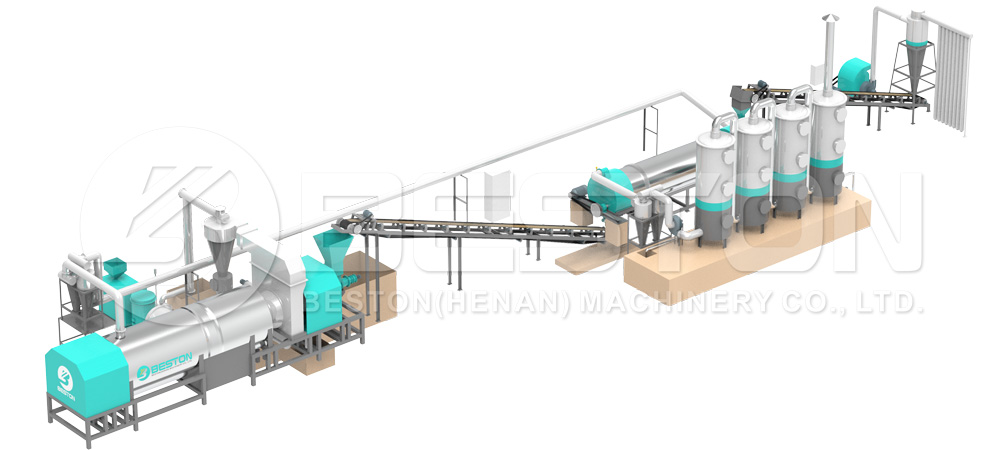

Wood Charcoal Making Machine

The Process Starts With Drying The Waste

Some waste is sufficiently dry to go ahead and put it in the machine “as-is” but most is not and will have to be dried. Many of the machines will also have a pre-dryer that uses waste heat from the reactor chamber to dry the raw materials. Other times it’s actually better to have a crusher/dryer machine for raw materials like coconut shells, wood debris, and other large items. Chopping has two purposes, one, it makes the material ride up the conveyor belt smoothly and it also helps the material heat in a uniform manor inside the chamber.

Once inside the chamber, in the absence of oxygen, the materials are heated to a very high temperature, this is called pyrolysis. Since there is no oxygen, the materials cannot burn or catch fire, they must decompose into smaller molecules. By using high heat and excluding oxygen, there are no toxic gases or chemicals created. The waste is decomposed without flame. Click here to know more: https://bestonpyrolysisplant.com/.

One Of The Byproducts Is Combustible Gas

Most carbonization machines need the addition of coal or gas in order to get up to temperature. After that, the waste materials will release enough combustible gas to keep the reactor going as long as more feed stock is kept coming. This saves an enormous amount of money in running the machine as well.

In many cases there is also enough of the combustible gas to run the pre-dryer too saving even more money on energy. Depending on the type of waste material that is being fed into the machine, sometimes sufficient quantities of oil are also produced, at first as a gas and then condensed into oil. This oil can be sold on the open market where it is used in plenty of industrial processes or burned to heat homes, manufacturing plants, or run in ships.

Wood Charcoal Manufacturing Machine To Ghana

The Charcoal Is Highly Valuable

In a large part of the world many people still use charcoal to cook and heat their homes. It can also be used in a barbecue for picnics as well. One of the new emerging uses is to add it to the soil before planting on the farm. It helps crops grow faster and enriches the soil for many years to come. It also takes up to one thousand years to decompose completely, acting as a carbon sink storing carbon and saving the planet at the same time. Get high quality charcoal machine here.

If you’re wanting to make money from large amounts of agricultural waste this is an excellent method. You can charge to haul away the waste and then charge for charcoal and other byproducts making money on both ends of the deal. All the while helping the environment at the same time.