An egg carton making machine is utilized to create paper egg cartons. Typically, a paper egg carton plays a significant role in providing a protective layer for the eggs when they are stored or during their transportation. For this reason, paper egg cartons are commonly found in the supermarket in a wide range. But what are they made of exactly?

The raw materials required with this egg carton making machine are mainly different varieties of waste paper. They recycle waste paper to make paper egg cartons. Since the raw materials involved are generally easy to find, it can be relatively cheap to invest in an egg tray making machine, as well as an egg crate machine. Some examples of raw materials sources include waste newspaper, waste book, and waste paper carton.

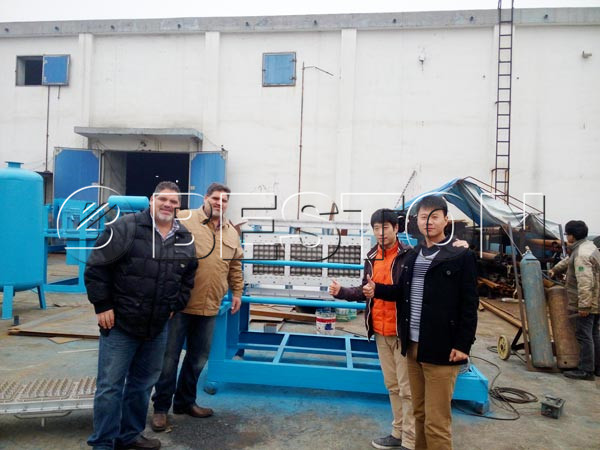

egg carton machine

Egg Carton Manufacturing Process

Now that you already know what an egg carton making machine is, let us take a look at the manufacturing process involved in making an egg carton. Majority of the investors find it essential to gain insight about the egg carton manufacturing process prior to starting a business. So what is the manufacturing process? The process can be subdivided into four phases: the pulp making process, the moulding process, the drying process and the packing process. Get high quality egg tray machine here.

1. Pulp Making Process

This process involves two stages, where the rough pulp is made and the other which requires refining. In the first stage, different types of waste paper are first inserted in the hydraulic pulper. The waste paper will then be turned into rough pulp by using water. In the refining stage, the rough pulp will go through the homogenization pool where it will be refined further using the help of a pulp beater found in the homogenization pool.

In this process, the right proportions of pulp will move into finished pulp. Paper pulp is then supplied into the forming machine by utilizing the pulp pump. Due to the vacuum pump’s suction power, the paper will eventually be absorbed in the moulds to create an egg tray. By using the air compressor, the formed egg carton will then be blown and eventually fall off from the moulds.

3. Drying Process

This is where additional water of egg cartons is evaporated. There are three drying choices you could consider:

– Make the drying line using bricks. Wet egg trays can be carried into the drying room using a belt conveyor. For fuel, diesel and coal can be used.

– Sun drying. This option of sun drying is most suitable for tiny egg tray manufacturing machine on sale. Besides, the appropriate wind and temperature are required. Once you meet these necessary conditions, you can then sun dry the wet egg cartons.

egg carton

– Metal drying line. Single layer and multi-layer drying lines are available for egg carton making machines. Wet egg trays can also be moved using a belt conveyor. With metal drying line, the installation is simple and covers a small area. Usually, diesel and natural gas are the choices for fuel. Find reliable one from pulp molding machine manufacturers here.

4. The Packing Process

This involves pressing of the paper egg cartons by using a carton press machine to reduce much space. Then, the stacking of paper crates will be done by a packing machine.