Pollution is one thing that mother earth has suffered from for an extended period. The cause of pollution either come locally or industrially from big manufacturing companies. The products like toxic fumes and waste that are non-biodegradable leads to global warming. Environmental enthusiasts are working tirelessly to create ways to curb this problem. Advancements in technology have eased the situation since machines can recycle items like waste plastic and tires. The pyrolysis plants work efficiently to achieve this goal and save the good little left for human beings. The device comes in varying designs, with the most recent being the mini skid mounted pyrolysis plant.

Get a Mobile Skid-mounted Pyrolysis Plant from Beston

Functions

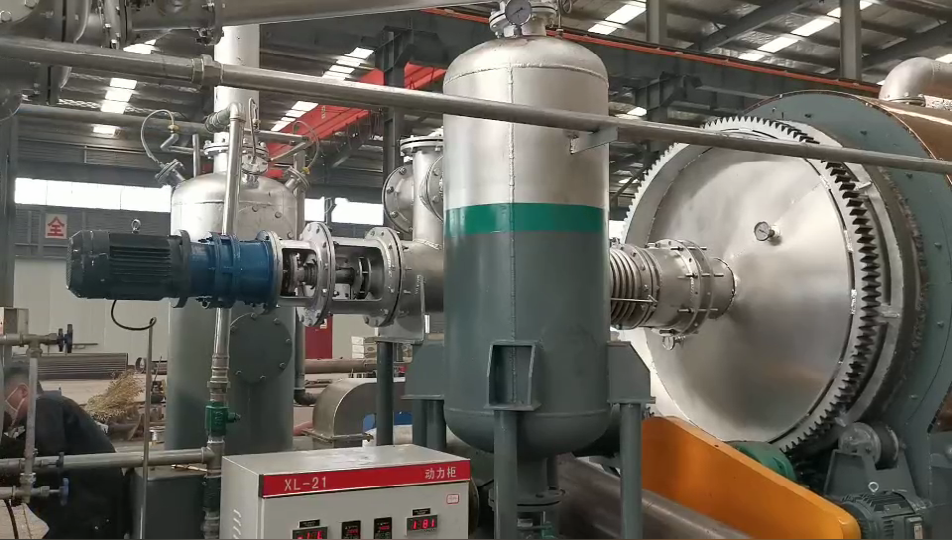

Pyrolysis is a recycling process where the machine uses heat to break more giant molecules to a smaller size. The plant has different chambers which the material goes through before it achieves its target. The first step of pyrolisis is feeding the raw materials on the reactor. Once you get the required amount, you shut the boot door and consequently seal it using the machine’s bolt. The sources of heat include coal, gas, or oil. The choice is dependant on availability and your financial capability. Heat the reactors to around 450 degrees. The products will start melting, producing a gaseous mixture of the components. The gas will evaporate and exit the reactor through the multiple stage operator and stored in a separate location. In the stage operator, there occurs the separation of the oil and gas residue. The gas further goes through a condensation process and cools down to form a liquid transferred to the receiver. See some projects in UK https://bestonmachinery.com/pyrolysis-plant/uk/.

Beston Skid Mounted Pyrolysis Pant Project

Benefits

The mini skid-mounted pyrolysis plant is one machine that has sufficiently recycled the different kinds of waste into something useful. The primary benefit of working with this machine is the ecologically sustainable way of production. During the reaction, there is no chance of the unsafe gas leaking into the atmosphere. At this level, the gas is full of toxins that the machines trap and eliminates. The device is user friendly and does not require any installation. You can transport it from one location to another.

Investing in the device is a way of creating employment in massive ways. You will hire people to get the waste material and others to oversee the pyrolysis process. The mini skid mounted pyrolysis plant gets to save the world from pollutants and also offer income to people, a win-win situation. Take a look at the related projects on https://getpocket.com/@37bp8T18A2f4dd85aNg91f9g28ddA83966bDxMwc37i9b1H10lk6eo58cfYAk71d.