Thailand, often referred to as the “Land of Smiles,” boasts a rich cultural heritage, stunning landscapes, and a diverse agricultural sector. In recent years, it has also emerged as a hotspot for sustainable technologies, including charcoal making machines. In this 3000-word post, we will explore the fascinating world of charcoal production in Thailand, from the traditional methods used by local communities to modern, efficient charcoal making machine in Thailand. We will delve into the benefits, applications, and environmental impact of charcoal production, shedding light on Thailand’s role in the global charcoal market.

Charcoal in Thai Culture and Tradition

To understand the significance of charcoal in Thailand, we’ll start with an exploration of its cultural and traditional uses. From cooking delicious Thai cuisine to participating in ancient rituals, charcoal holds a special place in Thai society.

Traditional Charcoal Making

For centuries, Thai communities have practiced traditional charcoal making methods. In this chapter, we’ll delve into these age-old techniques, which involve using kilns, pits, and local biomass materials.

The Rise of Modern Charcoal Making Machines

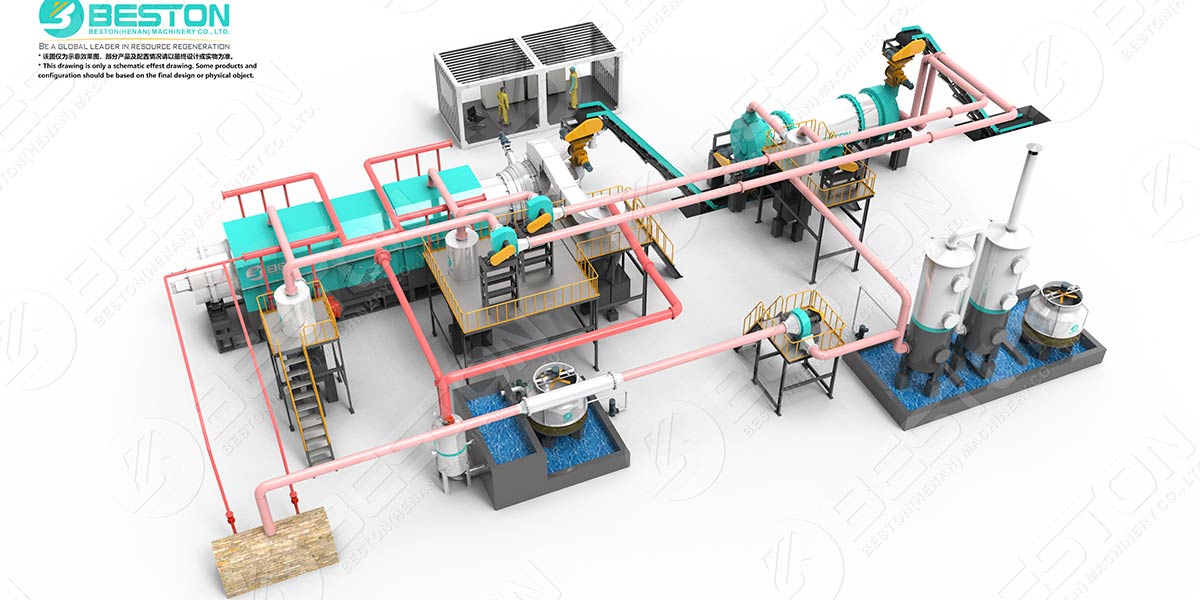

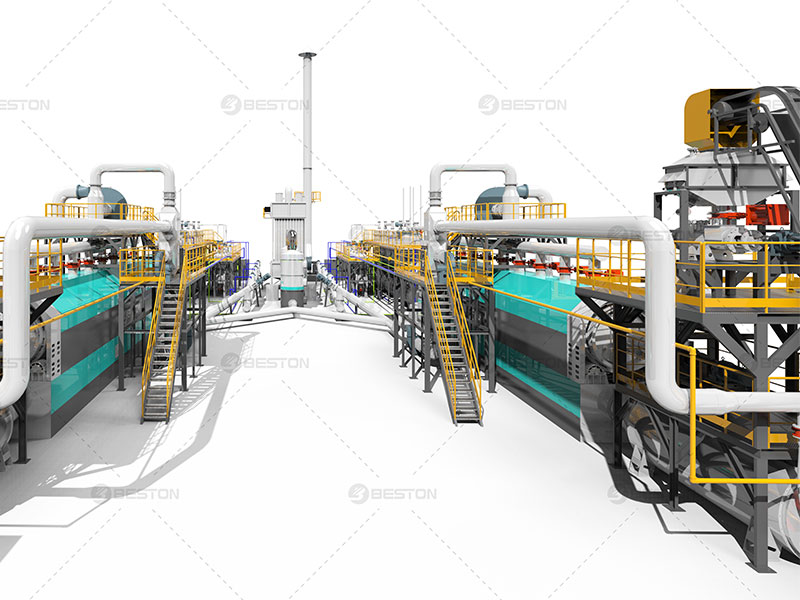

With the demand for charcoal growing, modern technologies have entered the scene. We’ll explore the evolution of Beston biochar pyrolysis equipment, highlighting their efficiency, safety, and environmental benefits.

How Charcoal Making Machines Work

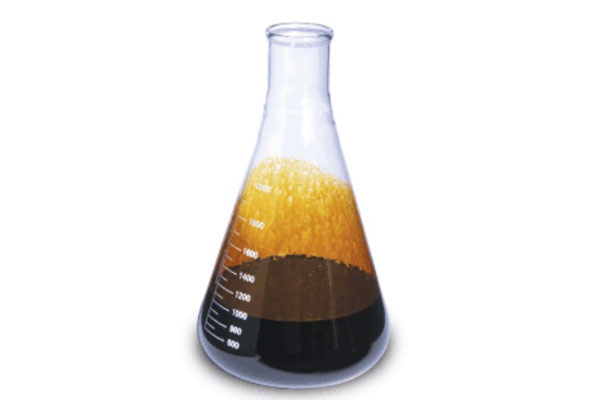

To grasp the mechanics behind these machines, this chapter provides an in-depth look at the pyrolysis process, from feeding biomass into the reactor to the collection of charcoal as the end product.

Types of Charcoal Making Machines

There is no one-size-fits-all solution when it comes to charcoal making machines. This chapter will examine the various types available, including batch and continuous systems, and their applications.

Benefits of Charcoal Making Machines

Charcoal making machines offer numerous advantages, from reduced emissions to efficient use of biomass resources. We’ll discuss these benefits and their implications for Thailand’s environment and economy. View the biochar machine manufacturer.

Sustainable Charcoal Production

Thailand is known for its lush forests and biodiversity. This chapter delves into the importance of sustainable charcoal production practices, including responsible sourcing of biomass materials and reforestation efforts.

Charcoal’s Role in Thai Agriculture

Charcoal’s benefits extend beyond the kitchen. We’ll explore how biochar, a type of charcoal, enhances soil fertility and crop yields, making it an invaluable asset for Thai farmers.

Exporting Thai Charcoal

Thailand’s high-quality charcoal has found a place in international markets. We’ll investigate the export trends, key destinations, and economic significance of Thai charcoal exports.

Challenges and Future Directions

No industry is without challenges. This chapter addresses issues such as sustainability, deforestation risks, and regulatory concerns, while also looking ahead to innovations and solutions.

The Charcoal Revolution in Thailand

In conclusion, Thailand’s charcoal industry is undergoing a transformation, blending age-old traditions with modern technology. As the world seeks sustainable alternatives to fossil fuels and deforestation, Thai charcoal and charcoal making machines stand at the forefront of this global revolution. By embracing these innovations, Thailand is not only preserving its natural beauty but also contributing to a greener and more sustainable future for the planet. View more information about machines on this web: https://bestonmachinery.com/biomass-charcoal-making-machine/.

Final Thoughts

Charcoal making machines in Thailand represent the perfect fusion of tradition and innovation, offering a glimpse into how ancient practices can adapt to meet the challenges of the modern world. As Thailand continues to evolve in its role as a charcoal producer and exporter, it underscores the importance of sustainability, responsible resource management, and the potential for positive environmental impact.