The common chicken egg is in high demand not only because of its nutritional goodness but also its versatility in every international cuisine. At any given moment, there are over 3 billion eggs in transit from hen houses to residential and commercial kitchens from Kingston to Kathmandu. Use the egg tray making machinery to make egg trays. The egg trays protect eggs.

To ensure that every last egg reaches its destination intact, they must be carefully transported in egg trays. This means that the demand for top-quality egg trays is second only to the need for fresh chicken eggs.

If you are looking to meet the needs of your local or international market with top-quality egg trays, you are at the right spot. In the following article, we will look at some of the more important considerations when choosing the right egg tray-making machine for your operations.

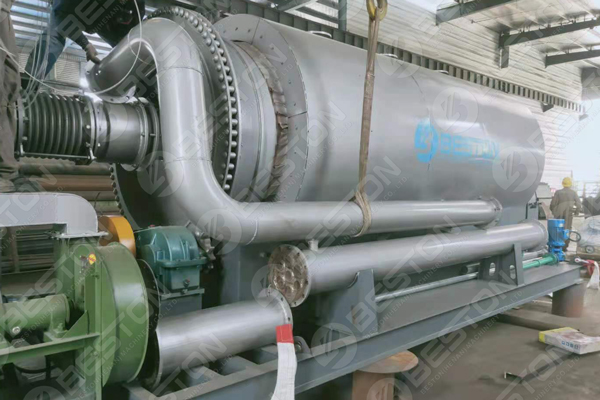

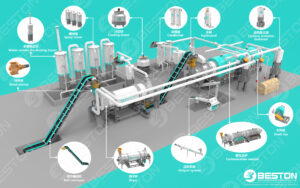

Beston Egg Tray Making Machine Shipped to Zambia

1.Consider your Needs

The best investments begin with proper planning. To begin your search for a suitable egg tray-making machine, you will need to consider your needs. List the values you would like to see emphasized in your investment as well as the details of your operational capacity that should be considered.

For example, if you are running a very large operation you need an egg tray-making machine capable of producing large quantities of products. The larger variety of egg tray-making machines can produce as many as 6,000 to 8,000 trays each hour. If you have a smaller operation, a heavy-duty egg tray-making machine is inefficient. It would be more economical to have two small machines running at full capacity than a larger machine operating at less than full capacity. Here is a case for your reference: egg tray making machine for sale in Pakistan.

You should also consider your local climate and weather conditions. The trays being produced are made of recycled paper products that are blended into a pulp and molded into trays. These will need to dry quickly and completely if they will retain their usefulness. If the weather in your local region is not conducive to fast-drying, you may want to consider purchasing a dryer component.

2.Budget Parameters

After you have a better idea of what you are looking for in an egg tray-making machine, it is time to decide on how much you have to spend on this investment. Different manufacturers of top-quality egg tray-making machines have different designs and components available to suit every need, but for a price. Make sure that you take the time to research the variety of components and systems specs you need. This way you won’t spend on anything that doesn’t serve your purpose. When you wanna know the price, click https://bestoneggtraymachine.com/egg-tray-making-machine-price-in-india/.

BTF4-4 Egg Tray Making Machine at Beston Manufacturing Factory

3.Shopping For Machines

Now that you know what you need and how much you are prepared to invest, you can begin contacting different manufacturers. They will take your needs and budget parameters into consideration and get back to you with their most suitable options. You can then compare the proposals you receive and favor the one that suits you the best.

In the end, the good egg box making machine for you will be the one utilizes the raw materials you have on hand to produce the products you need efficiently.