The 21st century has seen a lot of inventions come to life. One particular area has been the area of waste management. People have invented ways of dealing with waste; to recycle, reuse and reduce waste. As such, carbonization (https://www.bestoneco.com/planta-de-carbonizacion/)is a waste treatment technology used for processing biomass waste materials to yield useful byproducts.

What is Carbonization?

Carbonization is the destructive distillation of organic substances such as plants and dead animal remains into carbon. When complex carbonaceous substances like wood or agricultural leftovers are heated, they are broken down into carbon and chemical compounds that may or may not contain carbon in their chemical structure.

Proceso de Carbonizacion

These byproducts are utilized for use in other industries. In this way, waste is managed. This process is made possible by a carbonization machine. Carbonization machines(Hornos Metalicos para Hacer Carbon) work on biomass with low moisture content but are not limited to these alone. Note that this process seeks to obtain energy without carbon dioxide emission.

What Is a Carbonizing Machine?

A carboning machine is also known as a charcoal-making machine, biomass carbonization plant, or biomass pyrolysis plant. It uses waste treatment technology to dispose of biomass waste. In this sense, it uses biomass, materials such as peach nuclear, palm shells, coconut shells, plat stalks, rice husks, wood, wood chips, sewage sludge, and other materials to yield useful byproducts.

It works through a high-temperature pyrolysis process, which produces gaseous volatiles, sulfur emissions, and carbon byproducts. In the absence of air oxidation, such as in instances of incomplete thermal decomposition, the carbonization of biomass(Maquina para Hacer Carbon Vegetal) can also create charcoal and other by-products.

Carbon Negro

What is the carbonization process?

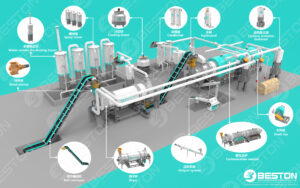

Carbonization is a process that involves heating biomass fuel in the absence of air at temperatures around 400°C (usually between 300 and 900°C) in a kiln or retort (pyrolysis). The carbonization process produces biochar, also known as charcoal, which is a porous, carbon-rich, greyish-black solid, after a sequence of processes. The process is as follows:

1. Forklifting the crushed biomass material into a silo

2. Using a belt conveyor to transport the materials to a quantitative feeder, then feed the materials into the biomass carbonization furnace at a consistent rate.

3. After passing through the cyclone, the flammable gas produced during the carbonization process enters the condensation analyzer system.

3. Following the cleansing by the spray dust collector, the combustible gas generated during the carbonization process passes via the cyclone and enters the condensation analyzer system.

4. A draft fan is then used to deliver wood vinegar into the machine for burning, which may provide continuous heat for carbonization. Note that there will be a lot of tar produced.

5. Burned high-temperature exhaust gas can also be used as a heat source for the drying system. By now, biomass waste has been converted to charcoal.

6. The tar and wood vinegar produced can be kept and sold as chemical raw materials.

Take Advantage of The Carbonizing Machine for Different Applications

Looking for a carbonizing machine?(Maquinaria Beston Benan) You can use it to manage agricultural and forestry waste, municipal waste, and even paper-making waste! It is a valuable investment. Reach out to us for more.