Biochar production has gained recognition as a vital solution for carbon sequestration and soil enhancement. The efficiency of biochar production depends on a variety of factors, ranging from feedstock preparation to the performance of the biochar making machine. Improving these aspects can significantly increase both the output and quality of biochar, making the process more economically viable and environmentally beneficial. Below are five key points to enhance biochar production efficiency.

1. Optimizing Feedstock Selection

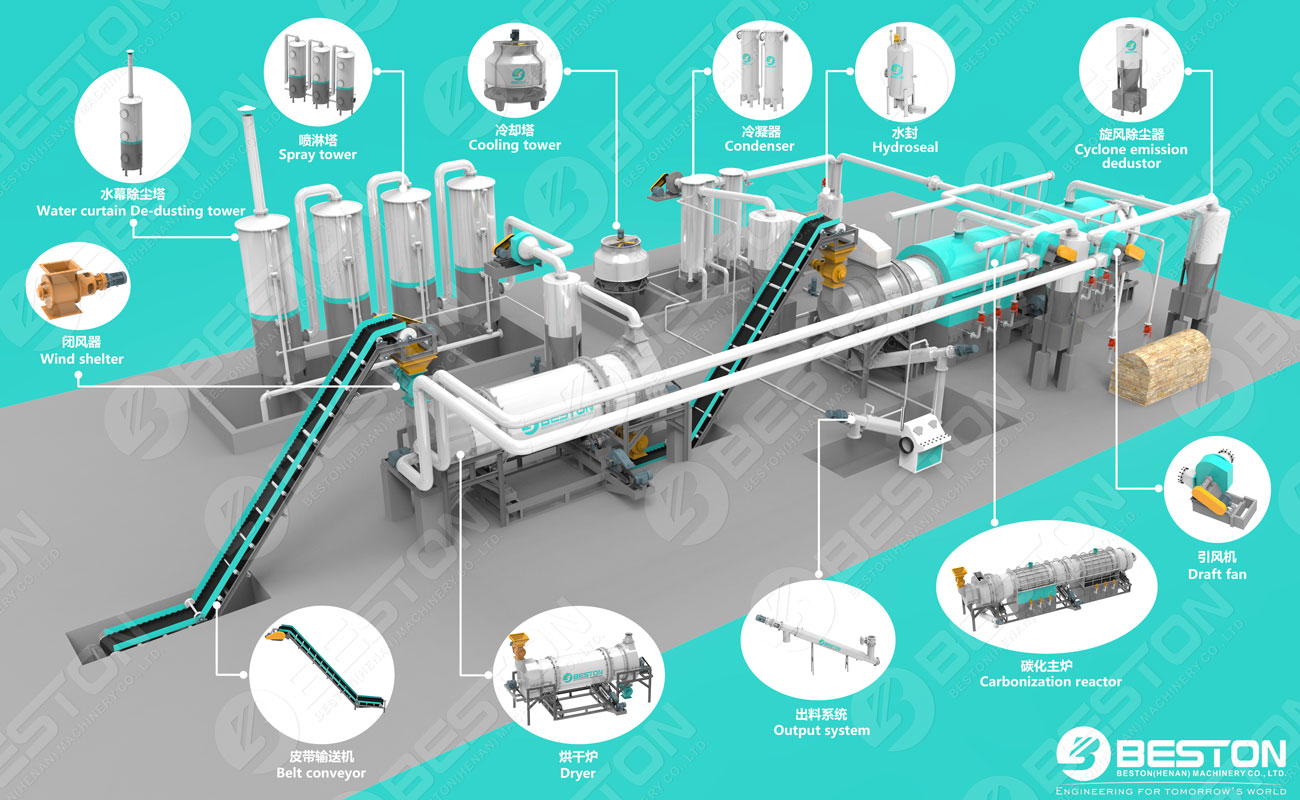

Feedstock plays a crucial role in determining the efficiency of biochar production. The composition and moisture content of the material directly impact the pyrolysis process, which is essential for producing high-quality biochar. Materials such as agricultural waste, wood chips, and biomass with a low moisture content typically yield better results. When selecting feedstock, it is important to ensure uniformity in particle size, as this allows for more efficient heating and uniform pyrolysis within the biochar making machine. Additionally, using feedstock with high carbon content results in biochar with higher carbon sequestration potential.

Pre-treatment of feedstock can also improve production efficiency. Methods like drying and grinding feedstock before pyrolysis can reduce the moisture content and create a more uniform material for processing. The quicker the material is heated during pyrolysis, the better the efficiency, as it prevents energy losses during the heating phase.

2. Temperature Control and Optimization

The temperature at which the pyrolysis process occurs is one of the most critical factors affecting biochar quality and yield. The biochar pyrolysis reactor should be capable of maintaining precise temperature control throughout the process to ensure optimal carbonization. Too low a temperature may result in incomplete pyrolysis, while excessively high temperatures can degrade the biochar and reduce its carbon content.

Typically, the pyrolysis process occurs at temperatures between 350°C to 700°C. Operating the machine within this range allows for maximum biochar yield while maintaining the integrity of the carbon structure. Implementing advanced temperature control systems within the machine can improve both the speed and efficiency of the pyrolysis reaction. This technology ensures that the heating process is more consistent, which leads to better biochar quality.

3. Effective Heat Utilization

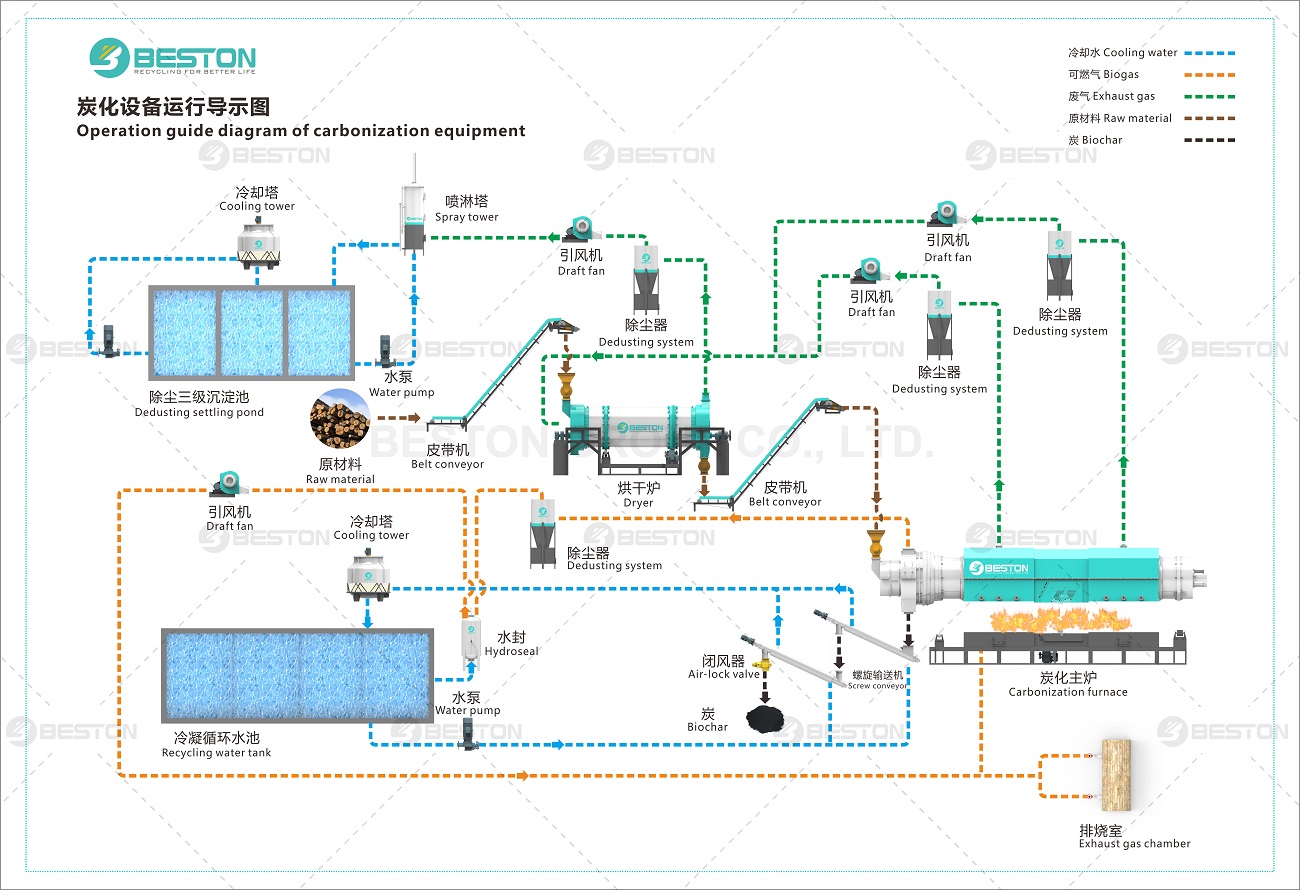

Maximizing energy efficiency is another way to improve the overall performance of biochar production. The pyrolysis process generates heat, which can be recycled and reused to fuel the biochar making machine. Utilizing heat recovery systems can significantly reduce the overall energy consumption of the process. By redirecting hot gases or using the energy generated during pyrolysis to maintain the desired temperature, operators can enhance both the efficiency and cost-effectiveness of the system.

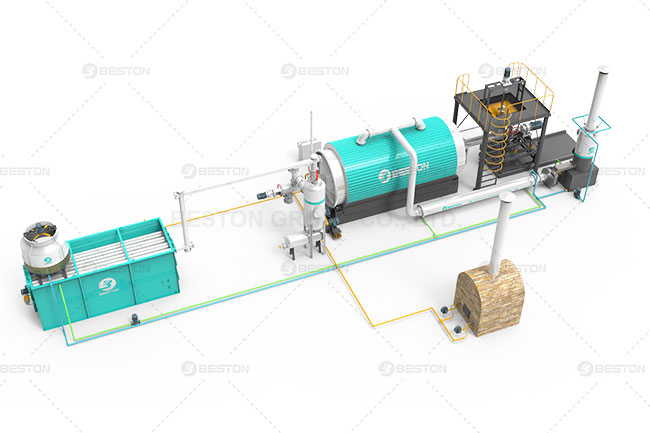

Some biochar reactor for sale comes equipped with integrated heat exchangers, which capture and store heat for later use. This not only reduces fuel consumption but also accelerates the pyrolysis process, leading to higher throughput and more consistent product quality. Integrating such systems within the biochar production process can lead to more sustainable operations.

4. Improved Gas Management

During pyrolysis, various gases, including volatile organic compounds (VOCs), are released. Efficient gas management is essential for improving production efficiency and environmental performance. Instead of allowing these gases to escape, many biochar making machines are designed to capture and either condense or use them as fuel for the pyrolysis process. By recapturing and reusing the produced gases, the overall energy balance of the system improves, thereby increasing efficiency. For the best exhaust gas management solutions, please visit: https://www.bestongroup.com/

Proper gas management systems also reduce emissions and minimize the environmental impact of biochar production. Effective filtration and gas cleaning systems help remove harmful substances from the released gases, ensuring that only non-polluting compounds are discharged. Additionally, incorporating these systems into the biochar production line leads to a more sustainable and efficient operation.

5. Automation and Process Control

Automation and advanced process control systems can significantly improve the consistency and efficiency of biochar production. By integrating sensors and automated feedback loops, the biochar making machine can constantly adjust operating parameters such as temperature, feedstock flow rate, and residence time. This allows for precise control over the pyrolysis process, reducing human error and enhancing the repeatability of biochar quality.

Furthermore, real-time data monitoring can provide valuable insights into the performance of the system, enabling operators to detect inefficiencies or malfunctions before they escalate. Advanced automation also leads to a reduction in labor costs and enhances the scalability of biochar production. As a result, the overall production process becomes more efficient, profitable, and adaptable to varying operational conditions.

Conclusion

Improving biochar production efficiency involves optimizing multiple aspects of the process, from feedstock selection to machine performance. By focusing on temperature control, heat utilization, gas management, and automation, it is possible to significantly increase both the quality and yield of biochar. Incorporating these strategies into biochar making machine operations not only enhances the economic viability of the production process but also supports broader sustainability goals. As demand for biochar continues to rise, maximizing production efficiency will become even more critical to meeting the needs of agricultural, environmental, and industrial applications.