The product of egg tray manufacturing is egg trays used for commercial production. The raw materials required in the process of making egg trays are raw wood pulp, fine craft paper, aged newspaper, thick paper, egg shells, wooden chips and many others. Get the paper egg tray making machine.

Egg tray making machine is basically a type of pulp making machine that can transform used paper into egg shells, egg nests, and plastic egg cartons. The current statistics indicate that billions of plastic egg boxes or plastic egg trays are required in the transportation or storage process, making the profit margin for such machines pretty high… and it all adds up to millions of dollars! It’s a fact! How’s that for business? Anyway, if you’re one of those interested people who are looking for such a machine and who want to start earning money with them, then keep reading.

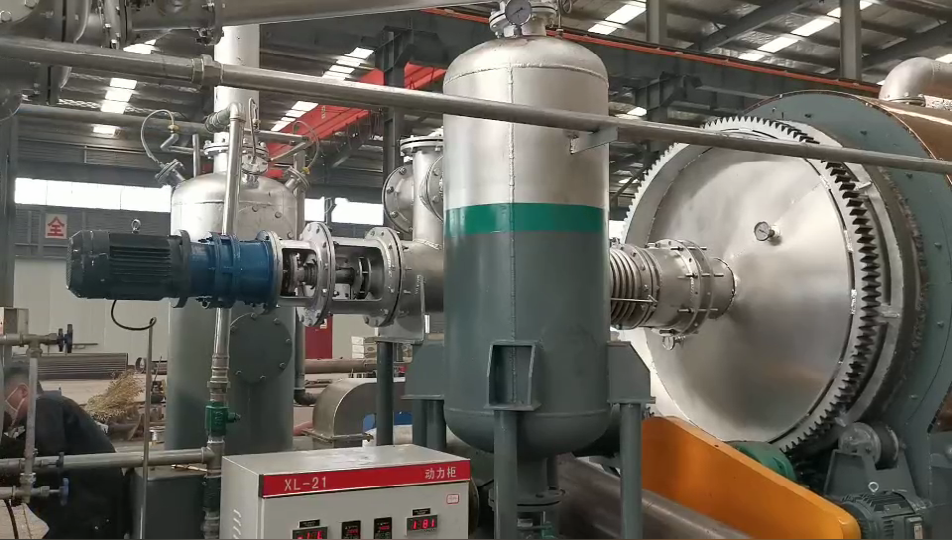

Paper Egg Tray Making Machine for Sale

The basic things you need to build your own automated egg t ray making machine include a suitable machine to make egg shells, an injection mold to make egg-shaped cavities (which can be filled with melted chocolate, candies, dried fruits, etc. ), some nylon wires, some heat shrink wrap, an instruction manual, some silicone braid, some strong Velcro tape, some food-grade clay, some baking soda and some wood. Those are the common raw materials you will need to make a decent machine. Now, here are some tips on how to do the whole process properly. Get the egg tray machine for sale Philippines.

First of all, you must determine the production capacity of your egg tray manufacturing machine. How much mass can you produce per hour or per day? A rough calculation can be done by considering the volume of trays produced per hour, multiplied by the production capacity of the machine. The other thing to consider is the packing volume, which should be designed to cover the package and make sure that the package will be delivered to the right address and to the right person.

The best egg tray making machine is without a doubt an ideal product for preparing hard boiled eggs, soft-boiled egg whites, and hard-cooked eggshells. The machine is also able to make soft-boasted egg whites and soft-cooked egg spoons. These products are very popular on restaurant business or in family homes, where there is always a demand for home-cooked food. You can also make these products easily at your home by purchasing one of the many available egg making machines in the market. View the paper egg tray making machine in India.

You must ensure that you are purchasing an efficient egg tray making machine which offers the best quality. Moreover, you should look for a high production capacity so that you do not waste any of your production capacity. When you are shopping for a quality egg tray making machine, it is best that you check out the manufacturing capacity, the capacity of egg shells to be used, and the feed distribution.

BTF4-4 Beston Egg Tray Making Machine Installed in India

An egg tray making machine can cut down on your supply costs if you own or run a farm where you harvest your own eggs. Rather than buying the egg trays from someone else, you can just make your own. Get the machine from https://BestonMachinery.com/ right now.