When grains are harvested, there is nearly always plenty of leftover waste materials. Not only are there the stalks of the plants to consider, but nearly every grain has a hull, or husk, that hard outer shell that protects the inner grain kernel. While small in size, they add up to millions of tons of waste each year. Just rice hulls alone are over a million tons of waste in the rice growing countries. It is made up primarily of silica, carbon, and volatile oils and gases. Needless to say, finding a way to use this massive amount of waste is necessary in order to not have to place it all in landfills which are already overburdened worldwide. One of the newest strategies is to use rice husk charcoal making machine, here’s how.

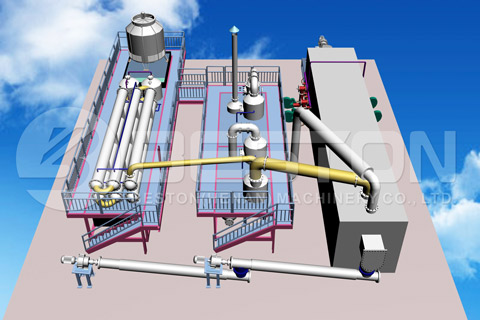

Rice Hull Charcoal Machine

Most Charcoal Making Machines Are Versatile

These charcoal making machines can take all kinds of agricultural waste and turn them into usable briquettes that can then be used as firewood. Many millions of people rely on cutting firewood daily in order to cook their food and there is a limited supply of firewood surrounding most population centers in the world.

A charcoal making machine can utilize the rice husks, shells of peanuts, stalks of plants, olive seed husks, waste wood, and nearly any other type of woody cellulose waste. This makes them invaluable for keeping millions of tons of waste from entering the landfills. In addition to that, once the briquettes have been made, they can supply millions of households with cooking fuel, which saves trees from being used. It can be the ultimate win-win-win situation for trees, landfills, and people all at the same time.

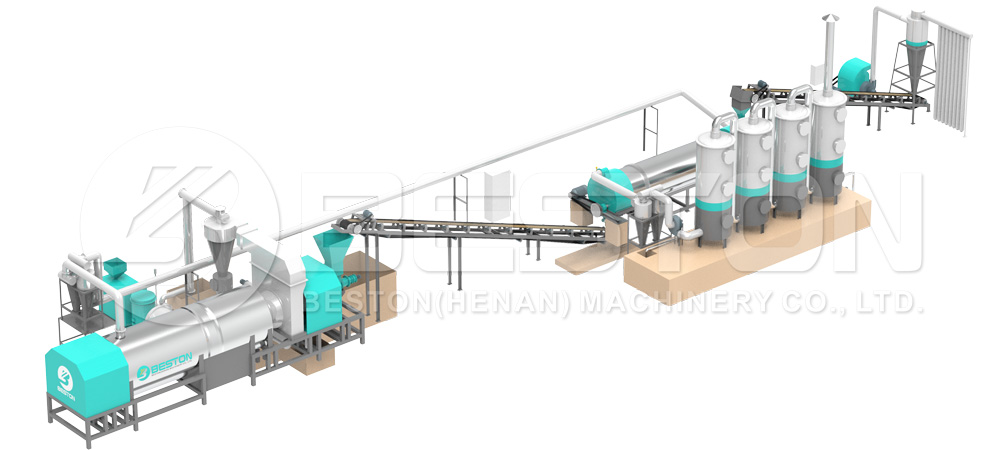

Charcoal Production Machine

How Does The Rice Hull To Charcoal Machine Work?

The first step in the process is called pyrolysis. That is when the cellulose material, whether rice hulls or wheat straw, is placed in the reaction chamber and is heated to a high degree. This is done in the absence of oxygen so that no combustion or fire can take place. Much of the volatile gases and oils evaporate out of the materials and what is left is charcoal.

The volatile gases and oils are in a vaporized state due to the heat. Then they are condensed into liquids and gases and used or sold. Many charcoal machines are made to run utilizing their own waste oils and gases to reduce their carbon footprint and save money at the same time. The charcoal that is made can vary in composition depending on the temperature that the charcoal production machine is set run at. The higher the temperature the more completely the organic matter is broken down.

If Briquettes Are The Desired Output

A lower temperature is better for making briquette quality charcoal. This will still have plenty of combustible material. The actual charcoal briquette making machine uses incredibly high pressure to compress the charcoal into briquettes with no additives at all in most cases.

If you need rice hull to charcoal making machinery, there are plenty of options available. Choose the machine from Beston that makes the right final product that you desire. Make sure you read the reviews of previous customers for longevity, parts availability, customer service, and durability. Then invest to save thousands of dollars in waste dumping fees and gain money in briquette sales while saving the environment.